TEM ALGUMA DÚVIDA? ESTAMOS PRONTOS PARA RESPONDER!

Você pode enviar consultas para obter orçamentos, planos e serviços exclusivos gratuitos.

Responderemos a todas as suas perguntas em até 24 horas.

Tampa inferior de metal banhada a ouro em formato de H para zíper

| produto | Acessórios para zíper |

|---|---|

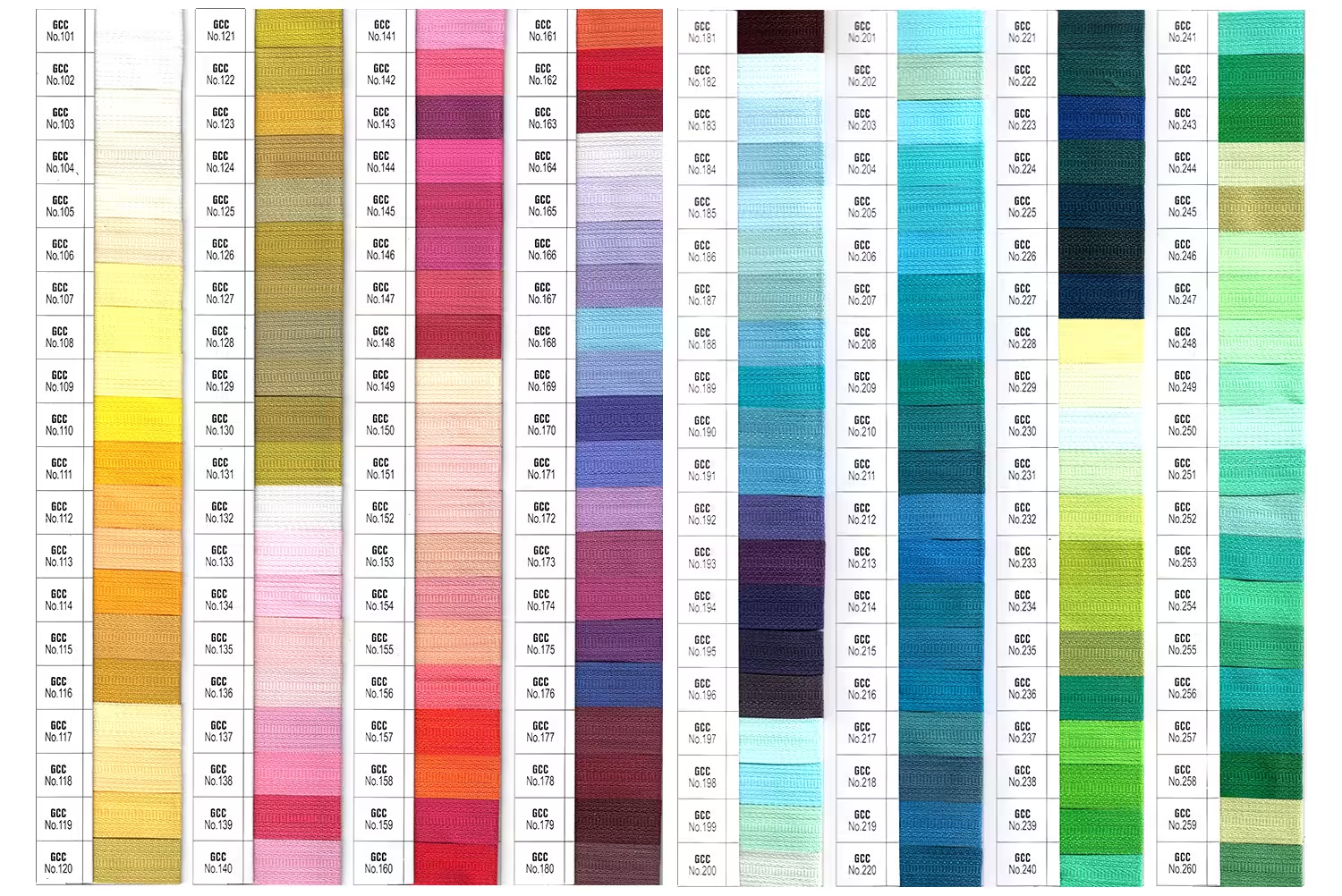

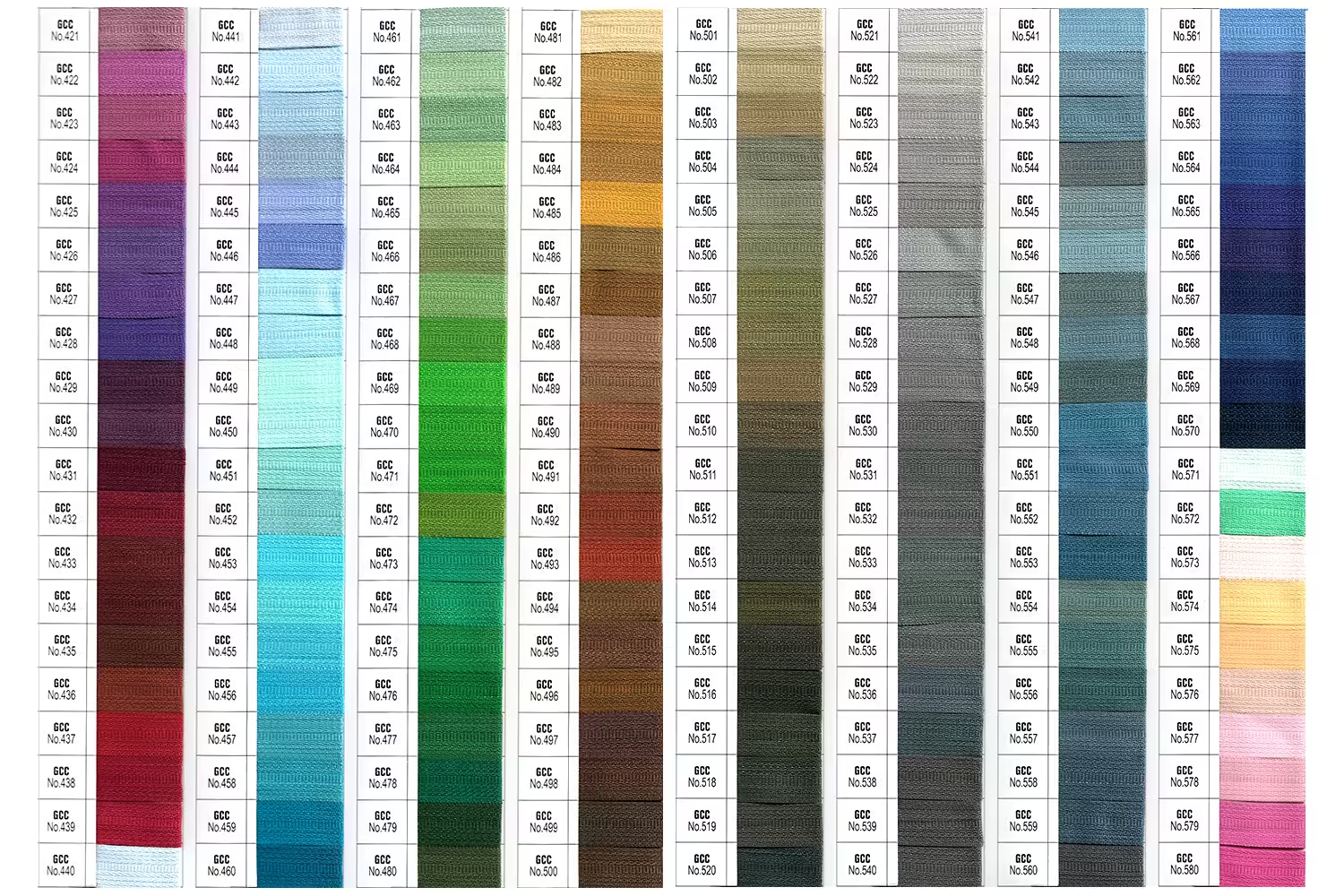

| cor | Personalizado |

| tamanho | 1#, 10#, 12#, 15#, 20#, 3#, 5#, 8# |

| Comprimento | Personalizado |

| aplicativo | roupas, têxteis, bolsas |

Este produto é personalizado de acordo com o design individual do cliente, portanto, não há preço fixo. O preço dependerá do material, tamanho, cores e quantidade. Saiba mais nas Perguntas Frequentes.

Tampas de fundo metálicas em formato de H são componentes essenciais em diversas aplicações industriais, conhecidas principalmente por sua estabilidade estrutural e durabilidade. Seu design exclusivo em formato de H não é arbitrário; ele oferece maior resistência à deformação e garante um encaixe seguro em diversos ambientes. Essas tampas são normalmente fabricadas em metais como aço inoxidável, alumínio e latão, escolhidos por sua resistência, resistência à corrosão e longevidade.

O design dos batentes inferiores metálicos em formato de H apresenta dois segmentos verticais paralelos conectados por uma barra horizontal, formando o característico formato de "H". Essa configuração distribui a tensão uniformemente por todo o batente, minimizando o risco de fadiga e falha do material. A geometria robusta do formato de "H" torna esses batentes particularmente adequados para aplicações pesadas, onde confiabilidade e desempenho são essenciais.

Diferentes metais são selecionados para a fabricação de tampas metálicas em formato de H, de acordo com os requisitos específicos da aplicação. O aço inoxidável, por exemplo, é preferido por sua excelente resistência à corrosão e resistência, tornando-o ideal para ambientes expostos à umidade ou produtos químicos. O alumínio, por ser leve e resistente, é frequentemente utilizado em aplicações onde a redução de peso sem comprometer a integridade estrutural é essencial. O latão, conhecido por sua trabalhabilidade e resistência ao desgaste, é comumente utilizado em aplicações de engenharia de precisão e decorativas.

A evolução dos batentes de fundo metálicos em formato de H remonta ao início da era industrial, quando a necessidade de soluções de fixação confiáveis levou a inovações no design dos batentes. Com o tempo, os avanços na metalurgia e nas técnicas de fabricação refinaram esses batentes, aprimorando seu desempenho e expandindo sua gama de aplicações. Hoje, os batentes de fundo metálicos em formato de H são indispensáveis em setores como construção, automotivo, aeroespacial e manufatura, destacando sua versatilidade e valor duradouro.

Batentes metálicos em forma de H tornaram-se componentes essenciais em diversos setores, reconhecidos por sua durabilidade e desempenho excepcional. Na construção civil, esses batentes são comumente utilizados em fundações e estruturas de edifícios. Seu design robusto garante maior capacidade de carga, tornando-os ideais para suportar estruturas pesadas. Por exemplo, em edifícios altos, os batentes metálicos em forma de H contribuem significativamente para a estabilização da estrutura, aumentando assim a segurança geral.

No setor automotivo, esses batentes são frequentemente empregados na fabricação de chassis de veículos e outros componentes estruturais. Sua resistência ao desgaste garante longevidade, mesmo nas condições mais exigentes. Engenheiros automotivos frequentemente preferem batentes inferiores metálicos em formato de H por sua capacidade de suportar altas tensões e vibrações, aumentando assim a durabilidade e a confiabilidade dos veículos. Um exemplo notável é seu uso em carros esportivos, onde desempenho e segurança são primordiais.

O setor industrial também se beneficia significativamente da aplicação de tampas metálicas em formato de H. Máquinas e equipamentos pesados, frequentemente submetidos a condições operacionais rigorosas, exigem componentes que possam suportar tensões mecânicas substanciais. As tampas metálicas em formato de H fornecem o suporte necessário, reduzindo o risco de falhas mecânicas e prolongando a vida útil das máquinas. Isso, por sua vez, resulta em menores custos de manutenção e maior eficiência operacional.

Um dos principais benefícios do uso de batentes metálicos inferiores em formato de H é sua maior capacidade de carga. O design exclusivo distribui o peso uniformemente, reduzindo a probabilidade de falhas estruturais. Além disso, sua resistência ao desgaste garante uma vida útil mais longa, tornando-os uma solução econômica para diversas aplicações. Sua longevidade é particularmente benéfica em ambientes onde a manutenção e a substituição representam desafios significativos.

No entanto, é importante reconhecer as potenciais desvantagens. O custo inicial dos batentes de fundo metálicos em forma de H pode ser mais alto em comparação com outros materiais. Além disso, seu peso pode representar desafios de manuseio durante a instalação. Apesar dessas considerações, as vantagens que oferecem em termos de desempenho e durabilidade muitas vezes superam o investimento inicial.

Concluindo, os batentes inferiores metálicos em forma de H desempenham um papel crucial no aumento da segurança, do desempenho e da longevidade de estruturas e máquinas em diversos setores. Sua capacidade de suportar cargas pesadas e resistir ao desgaste os torna um componente indispensável na engenharia e construção modernas.

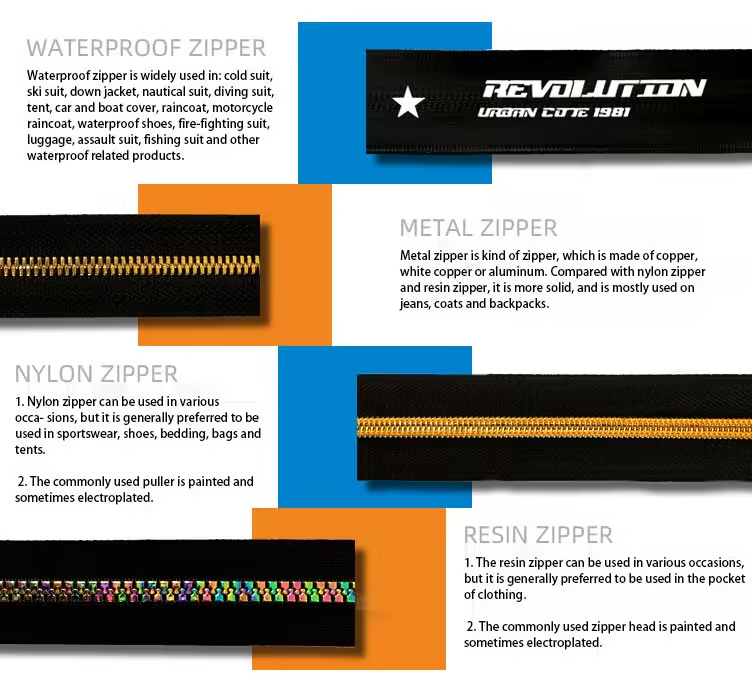

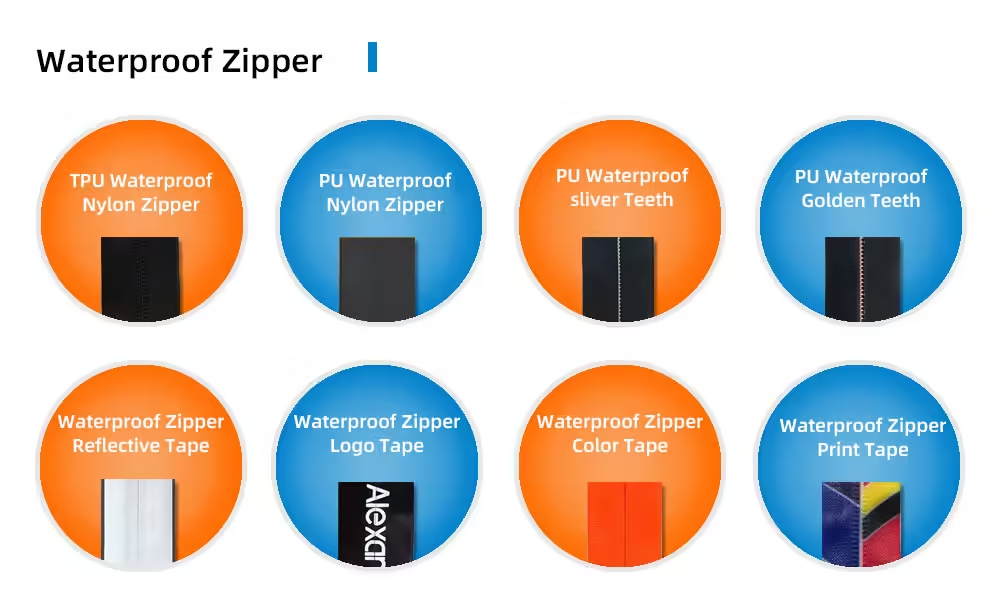

ZÍPER IMPERMEÁVEL

O zíper à prova d'água é amplamente utilizado em roupas de frio, roupas de esqui, jaquetas de plumas, roupas náuticas, roupas de mergulho, barracas, capas para carros e barcos, capas de chuva, capas de chuva para motocicletas, sapatos à prova d'água, roupas de combate a incêndio, malas, roupas de assalto, roupas de pesca e outros produtos à prova d'água.

ZÍPER DE METAL

Um zíper de metal é um tipo de zíper feito de cobre, cobre branco ou alumínio. Comparado aos zíperes de náilon e de resina, é mais resistente e é usado principalmente em jeans, casacos e mochilas.

ZÍPER DE NYLON

1. O zíper de nylon pode ser usado em diversas ocasiões, mas geralmente é preferível em roupas esportivas, calçados, roupas de cama, bolsas e barracas. 2. O puxador comumente usado é pintado e, às vezes, galvanizado.

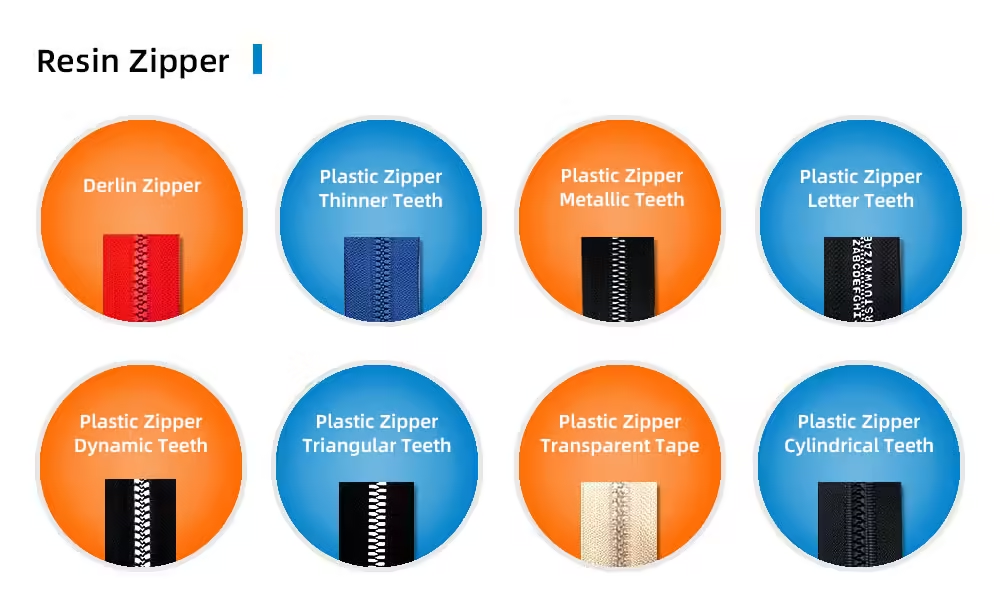

ZÍPER DE RESINA

1. O zíper de resina pode ser usado em diversas ocasiões, mas geralmente é preferível usá-lo no bolso da roupa. 2. A cabeça do zíper comumente usada é pintada e, às vezes, galvanizada.

Você pode enviar consultas para obter orçamentos, planos e serviços exclusivos gratuitos.

Responderemos a todas as suas perguntas em até 24 horas.

Entraremos em contato com você em até 1 dia útil, preste atenção ao e-mail com o sufixo “@zipper-factory.com”.