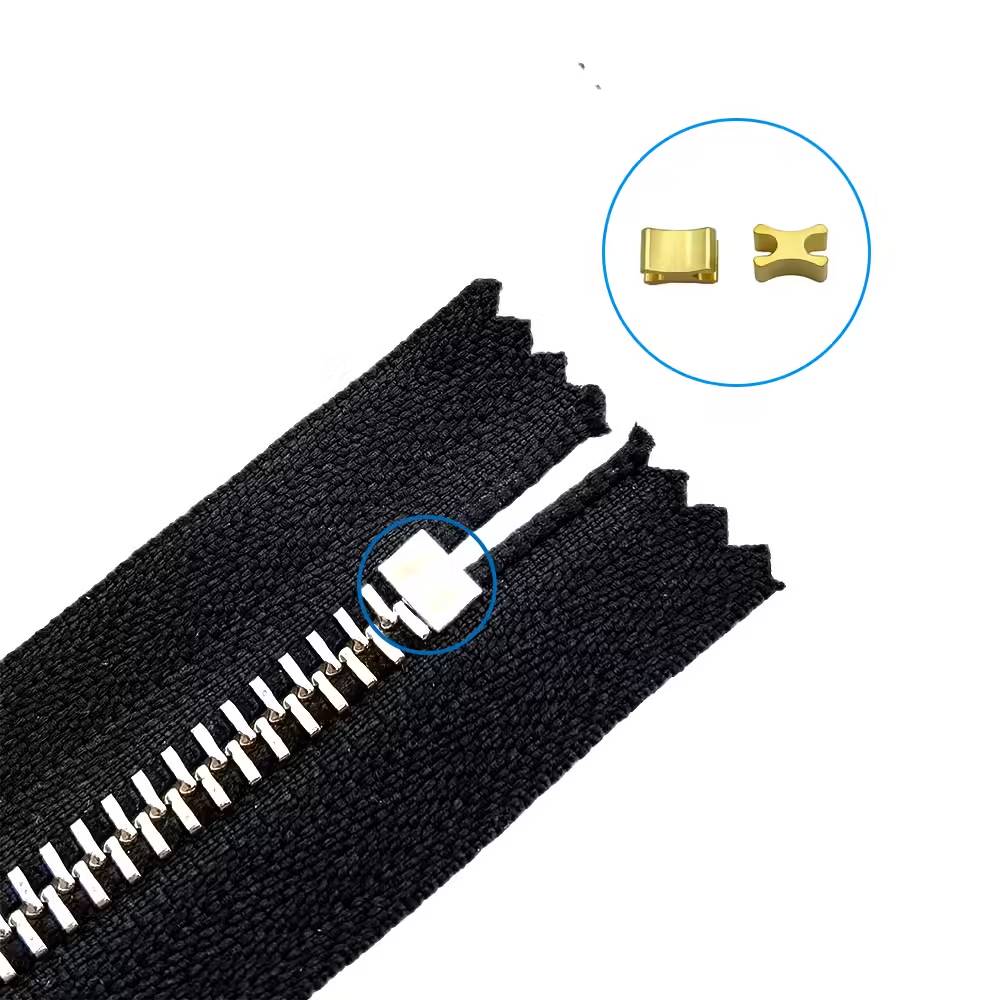

H Shaped Metal Bottom Stopper

H Shaped Metal Bottom Stopper

H Shaped Metal Gold Plating Bottom Stopper For Zipper

Additional information

| product | Zipper Accessories |

|---|---|

| color | Customized |

| size | 1#, 10#, 12#, 15#, 20#, 3#, 5#, 8# |

| Length | Customized |

| application | clothing,textile.handbag |

This product personalised to individual customer designs, so no fixed pricing.Pricing will depend on material, size, colours and quantity. Read more on the FAQ.

Introduction to H-Shaped Metal Bottom Stoppers

H-shaped metal bottom stoppers are integral components in various industrial applications, known primarily for their structural stability and durability. Their unique H-shaped design is not arbitrary; it provides enhanced resistance to deformation and ensures a secure fit in a multitude of settings. These stoppers are typically crafted from metals such as stainless steel, aluminum, and brass, chosen for their strength, corrosion resistance, and longevity.

The design of H-shaped metal bottom stoppers features two parallel vertical segments connected by a horizontal bar, forming the characteristic ‘H’ shape. This configuration distributes stress evenly across the stopper, minimizing the risk of material fatigue and failure. The robust geometry of the H-shape makes these stoppers particularly suitable for heavy-duty applications where reliability and performance are critical.

Different metals are selected for manufacturing H-shaped metal bottom stoppers based on the specific requirements of the application. Stainless steel, for instance, is favored for its excellent corrosion resistance and strength, making it ideal for environments exposed to moisture or chemicals. Aluminum, being lightweight yet sturdy, is often used in applications where reducing weight without compromising structural integrity is essential. Brass, known for its workability and resistance to wear, is commonly utilized in precision engineering and decorative applications.

The evolution of H-shaped metal bottom stoppers can be traced back to the early industrial era, where the need for reliable fastening solutions led to innovations in stopper design. Over time, advancements in metallurgy and manufacturing techniques have refined these stoppers, enhancing their performance and expanding their range of applications. Today, H-shaped metal bottom stoppers are indispensable in sectors such as construction, automotive, aerospace, and manufacturing, underscoring their versatility and enduring value.

Applications and Benefits of H-Shaped Metal Bottom Stoppers

H-shaped metal bottom stoppers have become integral components across various industries, renowned for their durability and exceptional performance. In the construction industry, these stoppers are commonly utilized in the foundation and structural frameworks of buildings. Their robust design ensures enhanced load-bearing capacity, making them ideal for supporting heavy structures. For instance, in high-rise buildings, H-shaped metal bottom stoppers significantly contribute to stabilizing the framework, thereby enhancing overall safety.

In the automotive sector, these stoppers are frequently employed in the manufacturing of vehicle chassis and other structural components. Their resistance to wear and tear ensures longevity, even under the most demanding conditions. Automotive engineers often prefer H-shaped metal bottom stoppers for their ability to withstand high stress and vibrations, thus improving the durability and reliability of vehicles. A notable example includes their use in sports cars, where performance and safety are paramount.

The industrial sector also benefits greatly from the application of H-shaped metal bottom stoppers. Heavy machinery and equipment, often subjected to rigorous operational conditions, require components that can endure substantial mechanical stress. H-shaped metal bottom stoppers provide the necessary support, reducing the risk of mechanical failure and extending the lifespan of the machinery. This, in turn, leads to lower maintenance costs and increased operational efficiency.

One of the key benefits of using H-shaped metal bottom stoppers is their enhanced load-bearing capacity. The unique design distributes weight evenly, reducing the likelihood of structural failure. Additionally, their resistance to wear and tear ensures a longer service life, making them a cost-effective solution for various applications. Their longevity is particularly beneficial in environments where maintenance and replacement pose significant challenges.

However, it is important to acknowledge potential drawbacks. The initial cost of H-shaped metal bottom stoppers can be higher compared to other materials. Additionally, their weight might pose handling challenges during installation. Despite these considerations, the advantages they offer in terms of performance and durability often outweigh the initial investment.

In conclusion, H-shaped metal bottom stoppers play a crucial role in enhancing the safety, performance, and longevity of structures and machinery across multiple industries. Their ability to withstand heavy loads and resist wear and tear makes them an indispensable component in modern engineering and construction.

Product Details:

Product Catategories

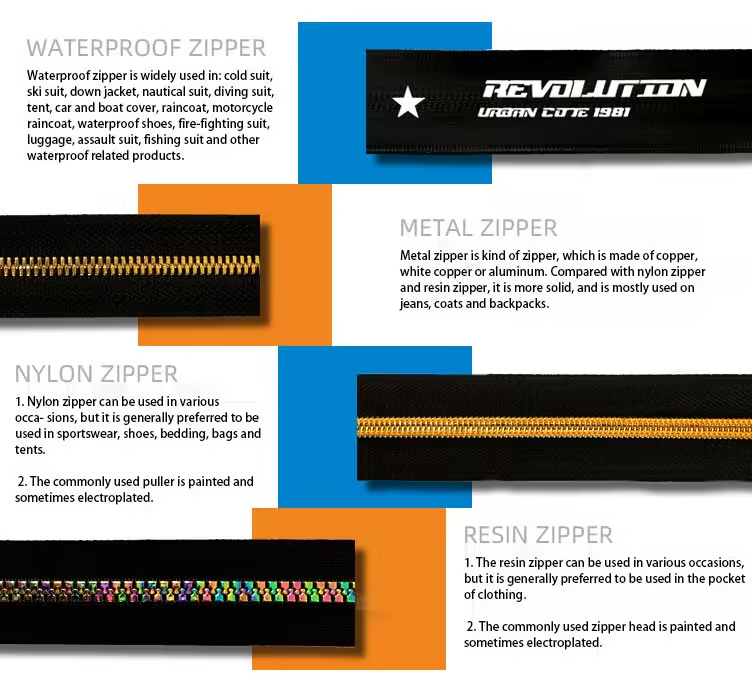

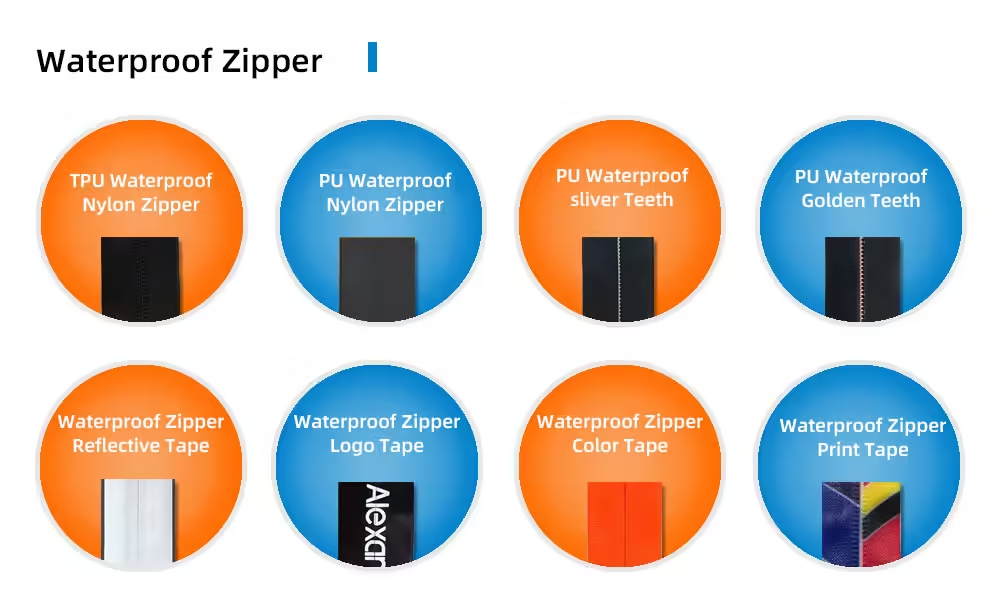

WATERPROOF ZIPPER

The waterproof zipper is widely used in cold suits, ski suits, down jackets, nautical suits, diving suits, tents, car, and boat covers, raincoats, motorcycle raincoats, waterproof shoes, fire-fighting suits, luggage, assault suit, fishing suit, and other waterproof related products.

METAL ZIPPER

A metal zipper is a kind of zipper made of copper, white copper, or aluminum. Compared with nylon zippers and resin zippers, it is more solid and is mostly used on jeans, coats, and backpacks.

NYLON ZIPPER

1. Nylon zipper can be used on various occasions, but it is generally preferred to be used in sportswear, shoes, bedding, bags, and tents.2. The commonly used puller is painted and sometimes electroplated.

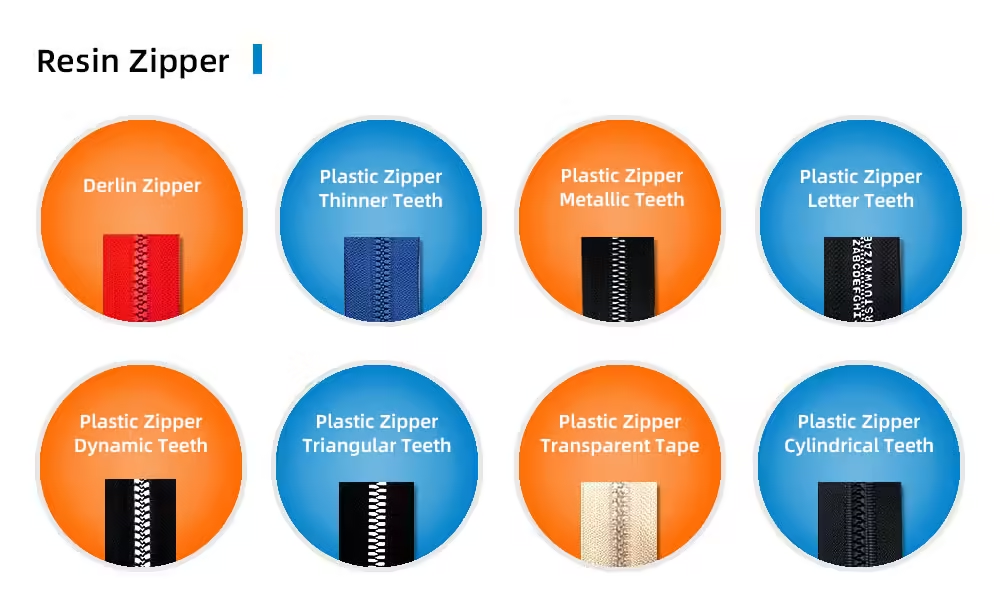

RESIN ZIPPER

1. The resin zipper can be used on various occasions, but it is generally preferred to be used in the pocket of clothing.2. The commonly used zipper head is painted and sometimes electroplated.

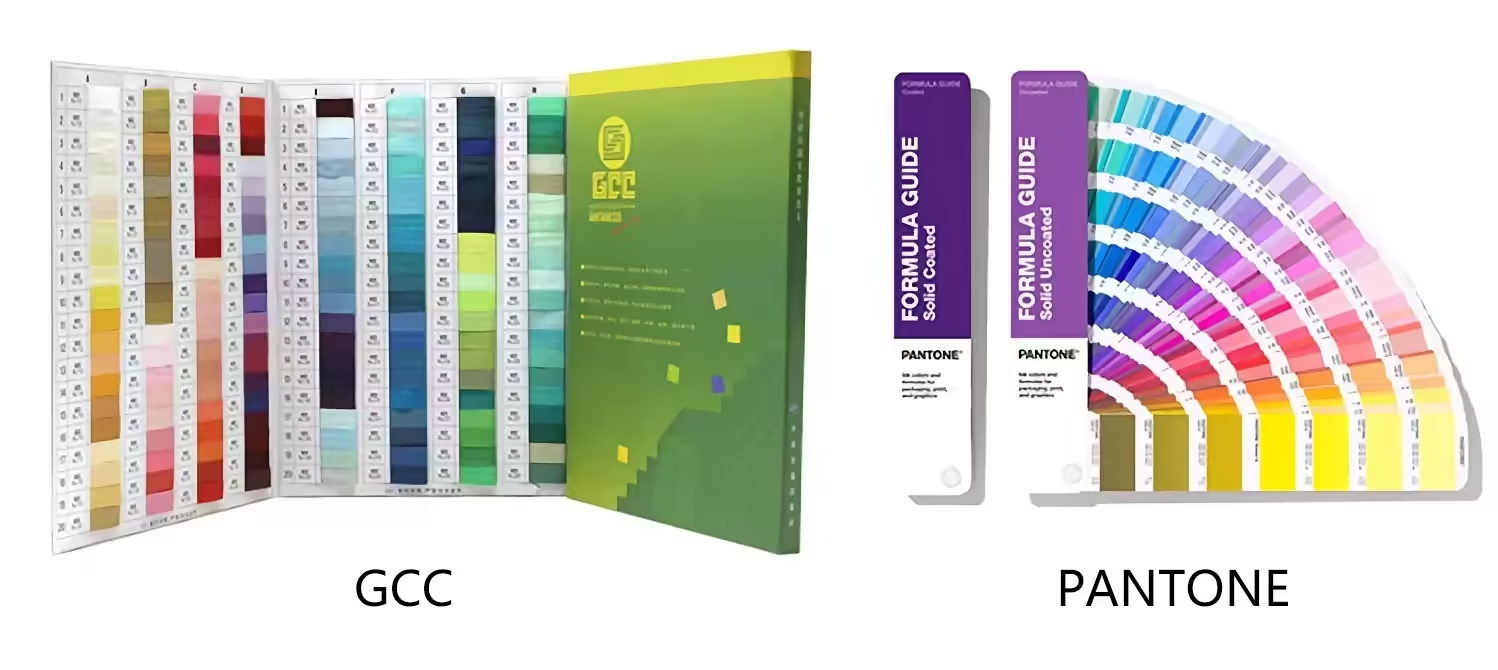

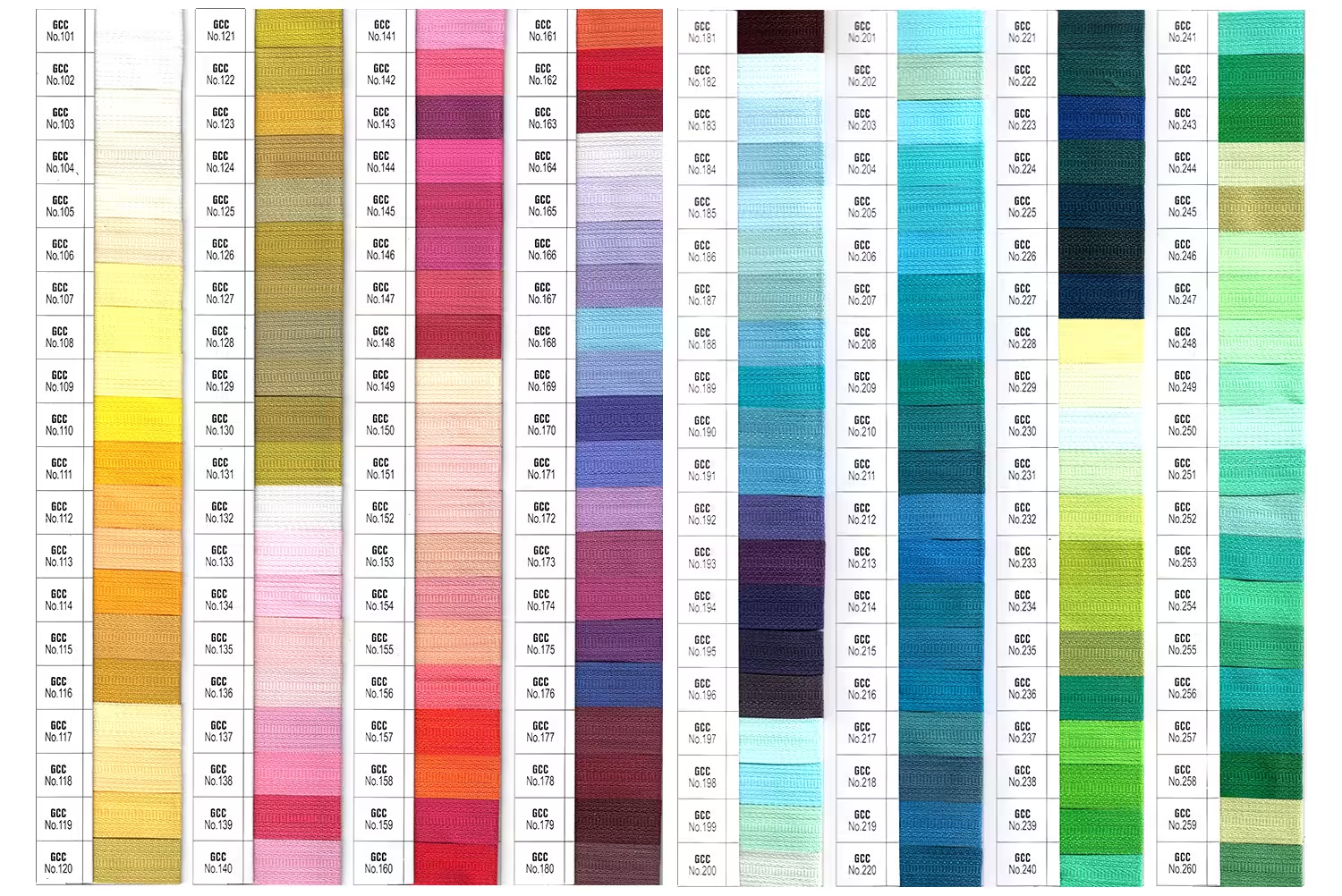

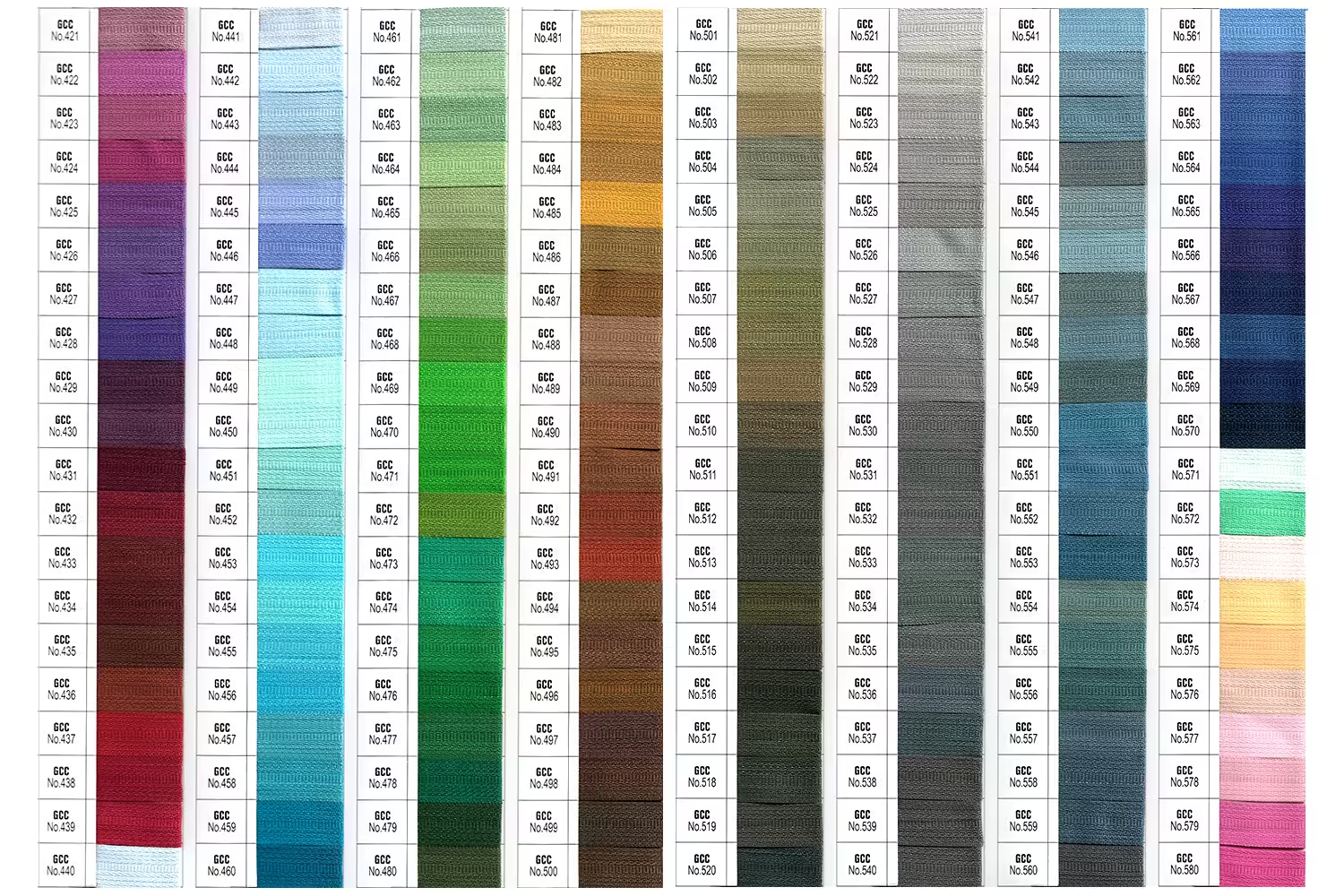

Custom Color

HAVE QUESTIONS? WE ARE READY TO ANSWER!

You can send inquiries to get free quotes, plans, and exclusive services.

We will reply to you with all your questions within 24 hours.