Heat Resistant Adhesive Tape For Zipper

Heat Resistant Adhesive Tape For Zipper

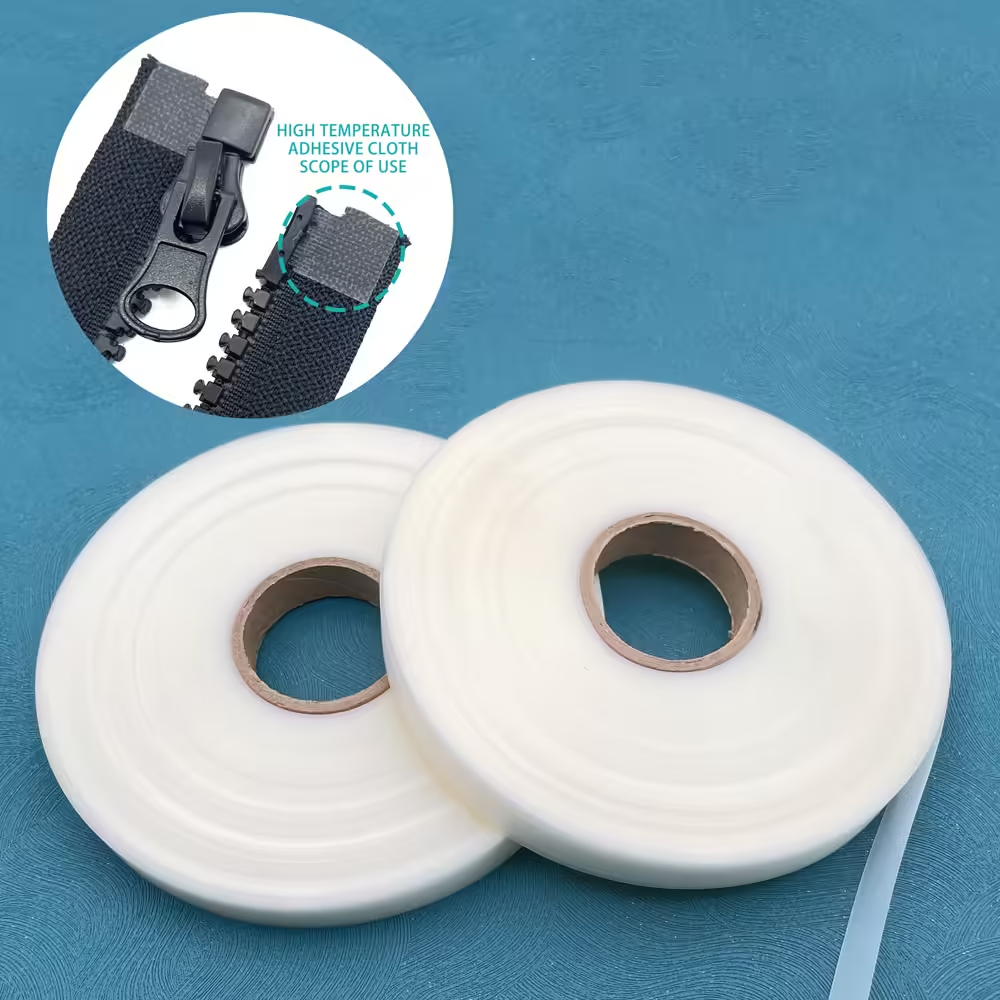

High Temperature Heat Resistant Cloth Adhesive Tape Translucent Zipper Tape For Install Zipper Pin And Box

Additional information

| product | Zipper Accessories |

|---|---|

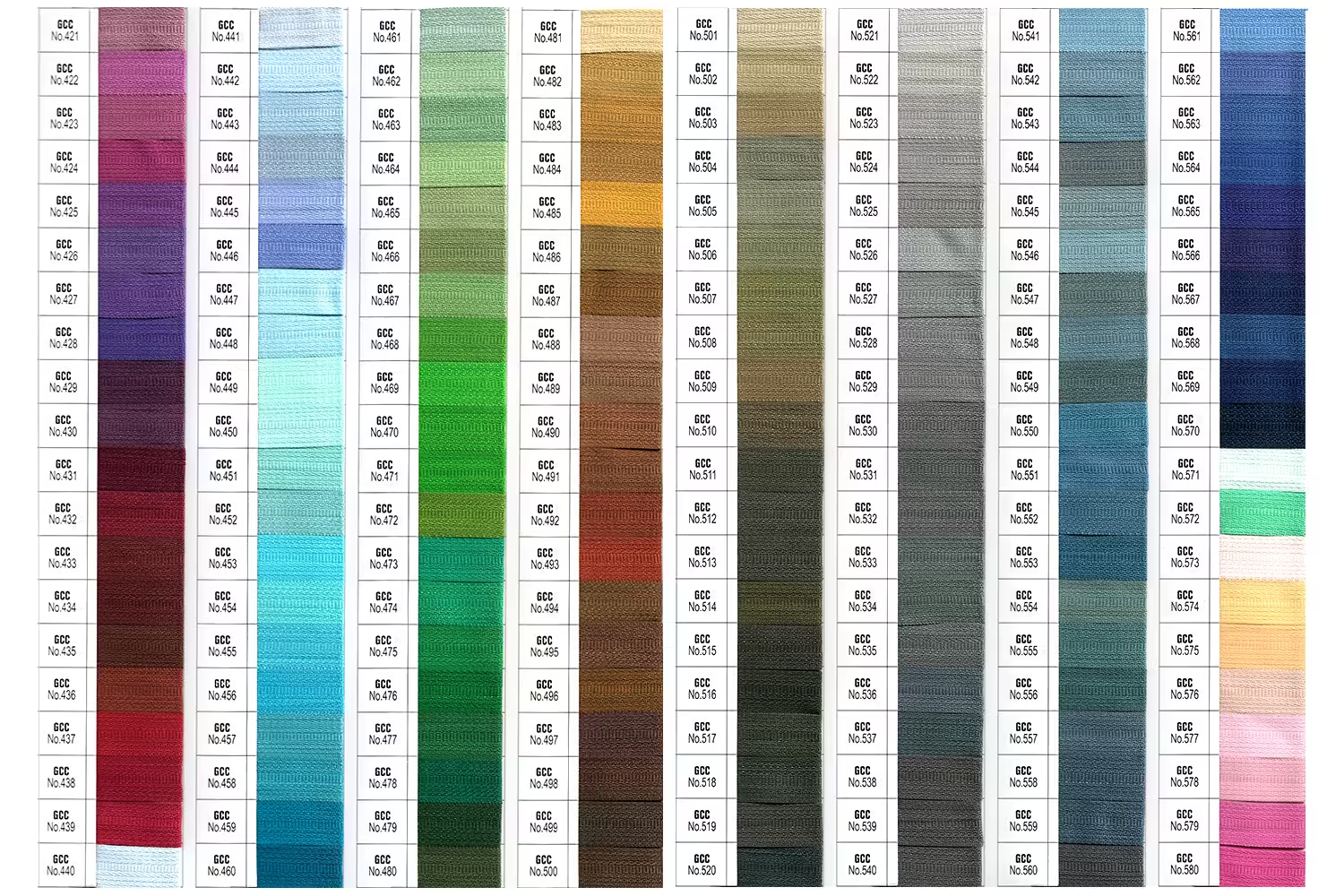

| color | Customized |

| size | 1#, 10#, 12#, 15#, 20#, 3#, 5#, 8# |

| Length | Customized |

| application | clothing,textile.handbag |

This product personalised to individual customer designs, so no fixed pricing.Pricing will depend on material, size, colours and quantity. Read more on the FAQ.

Understanding Heat Resistant Adhesive Tape: Properties and Benefits

Heat resistant adhesive tape is a specialized product designed to withstand high temperatures while maintaining its adhesive properties and structural integrity. This type of tape is particularly useful in applications where extreme heat is a factor, such as in the production and repair of zippers. The fundamental properties that make heat resistant adhesive tape unique include its ability to endure high temperatures without degrading, its robust adhesive strength, and its overall durability.

One of the primary benefits of using heat resistant adhesive tape for zippers is its enhanced longevity. Zippers are often subjected to significant mechanical stress and environmental factors, such as moisture and UV rays. Heat resistant adhesive tape ensures that the zipper remains functional and intact even under these challenging conditions. This improved performance under stress is crucial for both industrial and consumer applications, where reliability and durability are paramount.

Another key advantage of heat resistant adhesive tape is its resistance to environmental factors. Unlike standard adhesive tapes, which may lose their adhesive properties when exposed to moisture or UV light, heat resistant tape maintains its efficacy. This makes it an ideal choice for outdoor gear, automotive applications, and other scenarios where zippers are exposed to the elements.

When compared to other types of tapes commonly used with zippers, such as fabric tape or standard adhesive tape, heat resistant adhesive tape stands out as the superior option. Fabric tape can fray and degrade over time, while standard adhesive tape often fails when exposed to high temperatures or moisture. Heat resistant adhesive tape, on the other hand, offers a combination of durability, adhesive strength, and environmental resistance that makes it the preferred choice for many applications.

In summary, understanding the properties and benefits of heat resistant adhesive tape underscores its value in zipper applications. Its ability to withstand high temperatures, coupled with its durability and resistance to environmental factors, makes it an indispensable tool in both industrial and consumer settings.

Applications and Best Practices for Using Heat Resistant Adhesive Tape on Zippers

Heat resistant adhesive tape finds extensive applications across various industries due to its ability to withstand high temperatures while maintaining strong adhesion. One notable application is in the production of outdoor gear, where zippers frequently encounter harsh environmental conditions. For instance, in camping tents and hiking backpacks, the tape ensures that zippers remain functional despite exposure to intense heat from the sun or proximity to campfires.

In the realm of protective clothing, such as firefighting suits and industrial uniforms, heat resistant adhesive tape is crucial. The tape ensures that zippers remain securely fastened, providing an essential layer of protection for workers in high-temperature environments. Similarly, in high-temperature industrial settings, like metalworking or manufacturing plants, this tape ensures the durability and functionality of zippers on equipment covers and protective gear.

To achieve optimal results when applying heat resistant adhesive tape to zippers, follow these best practices. Begin with thorough surface preparation; clean the zipper area with isopropyl alcohol to remove dirt, grease, or other contaminants. Ensuring a clean surface is vital for maximum adhesion. Next, consider the environmental conditions during application. Ideal temperatures for applying the tape range between 15°C to 25°C (59°F to 77°F). Avoid applying the tape in excessively humid or cold conditions, as these can compromise the adhesive properties.

Applying the tape involves precise techniques. Measure and cut the tape to the required length, allowing a slight overlap at the ends for a secure fit. Press the tape firmly onto the zipper, using a roller or flat tool to eliminate air bubbles and ensure uniform adhesion. If any issues arise, such as lifting edges or poor adhesion, reapply the tape following the initial steps or consider using a primer designed to enhance adhesion.

Maintaining the integrity of the adhesive bond is crucial for the longevity of the tape’s performance. Regularly inspect the taped areas for signs of wear or damage. Clean the zippers using a mild detergent and water, avoiding harsh chemicals that could degrade the adhesive. Proper storage of the tape, away from direct sunlight and extreme temperatures, will also prolong its shelf life and effectiveness.

By adhering to these best practices, users can maximize the performance and durability of heat resistant adhesive tape on zippers, ensuring reliable functionality across various demanding applications.

Product Details:

Product Catategories

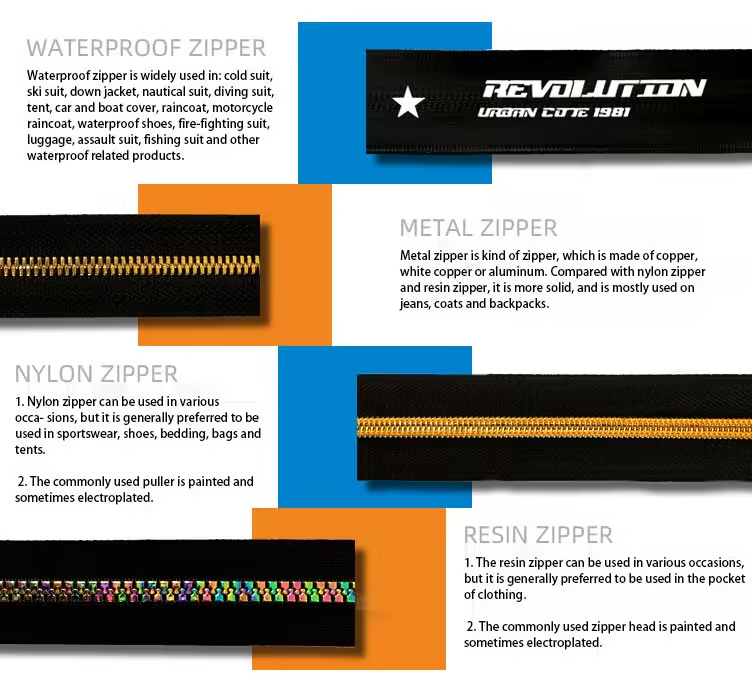

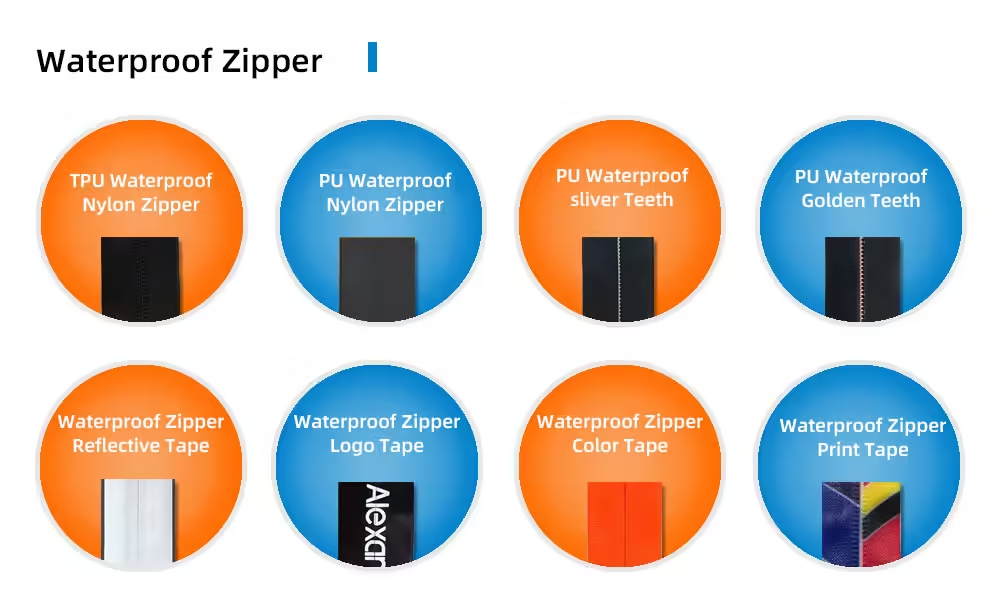

WATERPROOF ZIPPER

The waterproof zipper is widely used in cold suits, ski suits, down jackets, nautical suits, diving suits, tents, car, and boat covers, raincoats, motorcycle raincoats, waterproof shoes, fire-fighting suits, luggage, assault suit, fishing suit, and other waterproof related products.

METAL ZIPPER

A metal zipper is a kind of zipper made of copper, white copper, or aluminum. Compared with nylon zippers and resin zippers, it is more solid and is mostly used on jeans, coats, and backpacks.

NYLON ZIPPER

1. Nylon zipper can be used on various occasions, but it is generally preferred to be used in sportswear, shoes, bedding, bags, and tents.2. The commonly used puller is painted and sometimes electroplated.

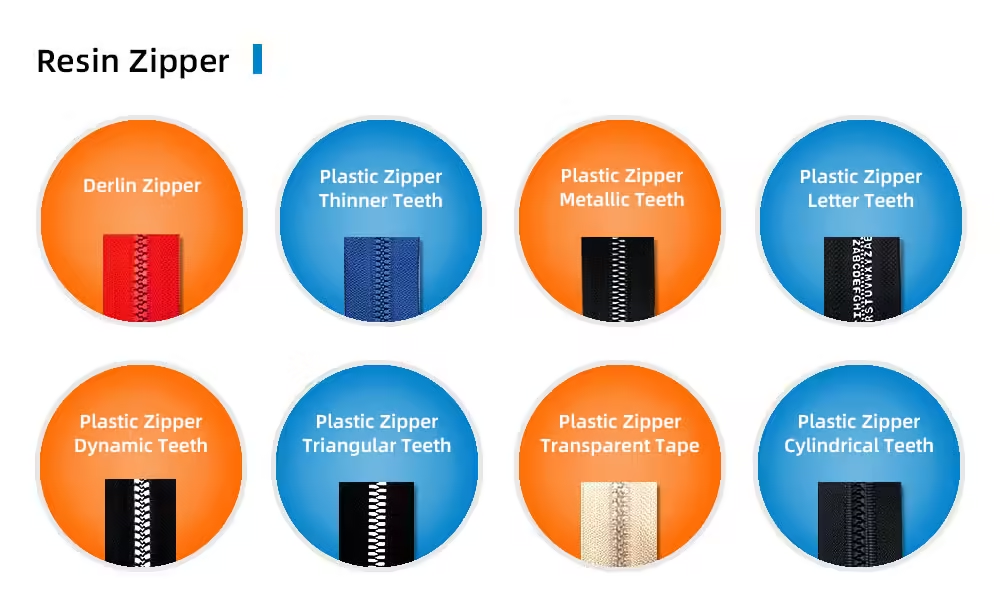

RESIN ZIPPER

1. The resin zipper can be used on various occasions, but it is generally preferred to be used in the pocket of clothing.2. The commonly used zipper head is painted and sometimes electroplated.

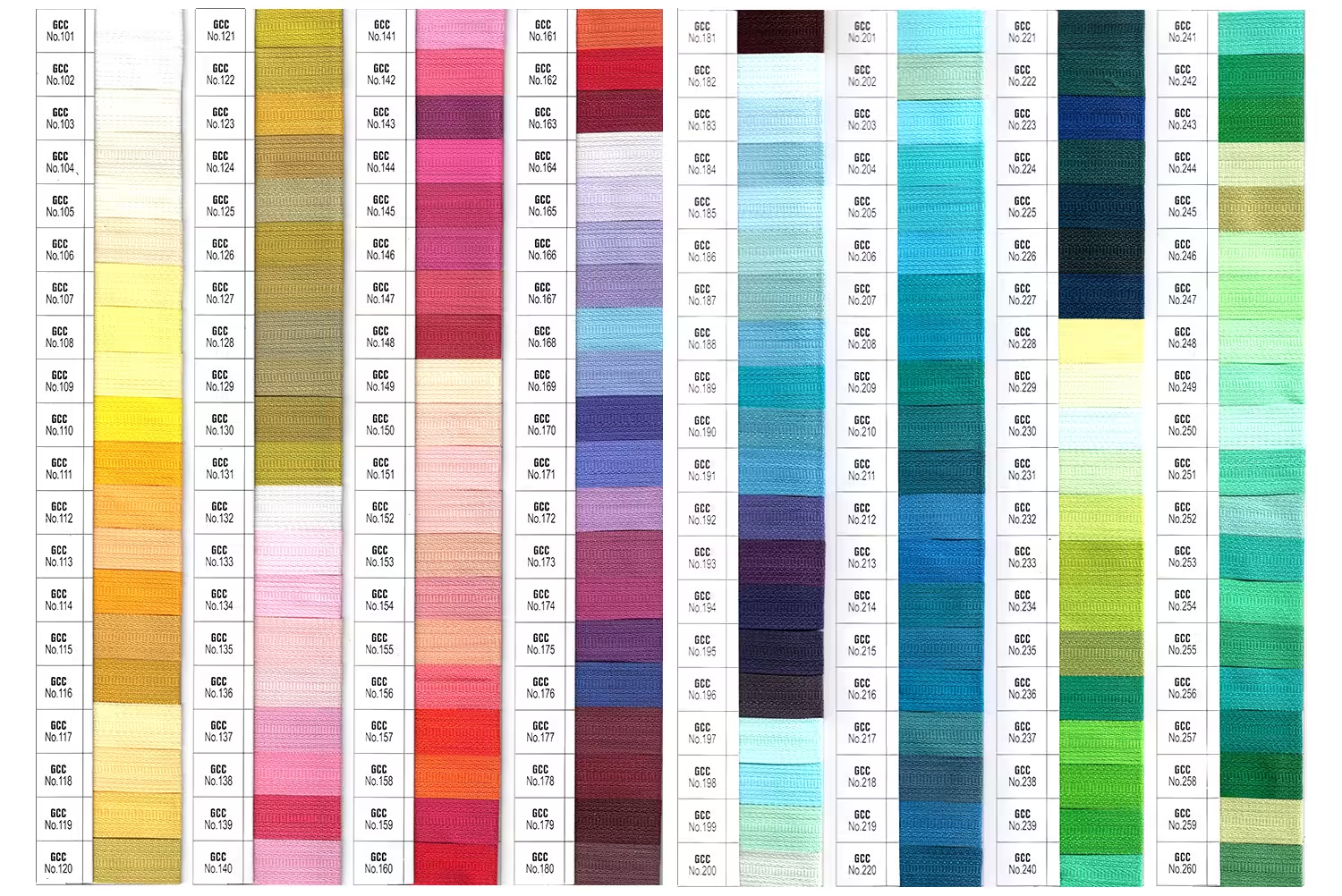

Custom Color

HAVE QUESTIONS? WE ARE READY TO ANSWER!

You can send inquiries to get free quotes, plans, and exclusive services.

We will reply to you with all your questions within 24 hours.