In luggage design, zippers are not just functional components; they directly impact the durability, security, and user experience of the suitcase. Below is a professional analysis of zipper selection for suitcases, focusing on key factors such as material, size, load-bearing capacity, and puncture-resistant design, along with some recommendations:

1. Material and Size Selection for Suitcase Zippers

Nylon zippers are widely used in suitcases due to their lightweight, flexible, and cost-effective nature. Their teeth are made by winding nylon monofilament, making them suitable for frequent opening and closing, with good corrosion resistance.

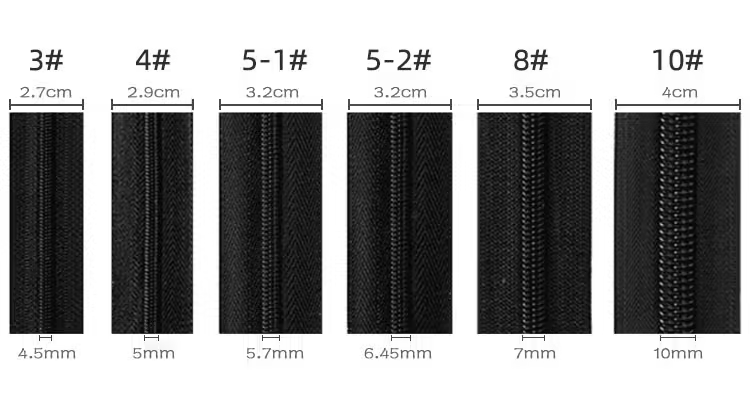

- Size (e.g., #8, #10) and Load-Bearing Relationship

The zipper size indicates the width of the teeth; the larger the size, the wider the teeth, and the greater the load-bearing capacity. For example:- #8 Zipper: Suitable for small to medium-sized suitcases, with a flat pull strength typically above 80N, meeting the needs of everyday travel.

- #10 Zipper: Commonly used for large-capacity suitcases or scenarios requiring high load-bearing capacity, with a flat pull strength of over 100N, ideal for carrying heavy items.

- Puncture Resistant Zipper: By increasing the number of nylon teeth layers, the tear resistance is further enhanced, reducing the risk of zipper bursts due to external pressure.

2. Testing and Performance Verification of High-Load Zippers

- Industry Testing Standards

According to QB/T 2171-2001 (Metal Zippers) and QB/T 2173-2001 (Nylon Zippers) standards, zippers must pass the following tests:- Flat Pull Strength Test: Simulates the zipper’s maximum load-bearing capacity when fully loaded, such as a #10 nylon zipper needing to achieve ≥100N flat pull strength.

- Smoothness Test: Uses professional instruments (e.g., SG-8072 tester) to evaluate the smoothness of zipper operation, ensuring flexibility even after prolonged use.

- Practical Application Data

Tests show that puncture resistant zipper, at the same size, have a load-bearing capacity approximately 30% higher than single-layer zippers, with superior deformation resistance. For example, a #10 double-layer nylon zipper can withstand a pull force of 130N, far exceeding ordinary designs.

3. Design Advantages of Puncture-Resistant Zippers

- Structural and Material Innovations

- Dense Teeth Arrangement: Reduces gaps for external puncture forces by narrowing the spacing between teeth or using interlocking designs.

- Application Scenarios

Puncture-resistant zippers are particularly suitable for business suitcases or outdoor travel cases, effectively preventing sharp objects (e.g., keys, tools) from accidentally puncturing the case while enhancing anti-theft capabilities.

By scientifically selecting zipper materials and structures, combined with rigorous testing data verification, the reliability and lifespan of suitcases can be significantly improved. For further information on selecting luggage zippers, feel free to contact us.