Camouflage Resin Zipper

Camouflage Resin Zipper

Custom Pattern Plastic Zipper Heat Transfer Zipper Camouflage Zipper For Tactical Uniforms

Additional information

| product | plastic zipper |

|---|---|

| color | Customized |

| size | 30# |

| Length | Customized |

| application | bag |

This product personalised to individual customer designs, so no fixed pricing.Pricing will depend on material, size, colours and quantity. Read more on the FAQ.

Understanding Camouflage Resin Zippers

Camouflage resin zippers represent a sophisticated fusion of innovative materials and cutting-edge design, tailored for a variety of applications. These zippers are primarily composed of high-quality resin, a versatile polymer known for its resilience and adaptability. Unlike traditional metal or plastic zippers, resin zippers offer a unique blend of durability and flexibility, making them a popular choice in industries where strength and subtlety are paramount.

The production process of camouflage resin zippers involves the incorporation of advanced camouflage patterns directly into the resin material. This is achieved through a meticulous process of embedding dyes or pigments within the resin before it is molded into zipper components. The result is a zipper that not only performs reliably but also seamlessly blends into a variety of environments, making it ideal for military, outdoor, and tactical gear.

The types of resin used in these zippers are specifically selected for their robustness and longevity. Typically, polyurethane and polyethylene resins are favored due to their excellent wear resistance and ability to withstand harsh environmental conditions. These materials offer a significant advantage over traditional metal zippers, which can corrode or jam, and plastic zippers, which may become brittle over time.

One of the notable benefits of resin zippers is their lightweight nature, which contributes to the overall comfort and functionality of the end product. Additionally, the flexibility of resin allows for smoother operation and less likelihood of snags or breaks, enhancing the user experience.

From an environmental perspective, the production of resin zippers is increasingly focusing on sustainability. Manufacturers are exploring bio-based resins and recycled materials to reduce the ecological footprint. These eco-friendly versions aim to offer the same durability and performance while minimizing environmental impact, aligning with the growing demand for sustainable manufacturing practices.

In essence, camouflage resin zippers stand out due to their superior combination of durability, flexibility, and aesthetic versatility, making them a pivotal component in various specialized applications.

Applications and Benefits of Camouflage Resin Zippers

Camouflage resin zippers have established themselves as indispensable components in various industries, owing to their unique blend of functionality and aesthetic appeal. One prominent area of application is outdoor and military gear, where these zippers are frequently integrated into tactical backpacks, hunting jackets, and outdoor tents. The camouflage design not only aids in concealment, making it ideal for military and hunting purposes, but also adds a rugged, outdoor look that appeals to enthusiasts and professionals alike.

In the realm of fashion, camouflage resin zippers have carved a niche for themselves. They are often used in jackets, cargo pants, and accessories, providing a stylish edge while maintaining their practical benefits. The fashion industry has embraced these zippers for their ability to merge utility with trendiness, making them a popular choice among designers and consumers who prioritize both form and function.

Sporting equipment is another domain where camouflage resin zippers offer significant advantages. Items such as outdoor sports bags, fishing gear, and camping equipment benefit from the durability and weather resistance these zippers provide. Their resilience in extreme conditions—be it rain, snow, or high humidity—ensures that the gear remains functional and reliable, which is crucial for outdoor activities.

Beyond their aesthetic value, the practical benefits of camouflage resin zippers cannot be overstated. Their enhanced durability makes them resistant to wear and tear, while their weather-resistant properties ensure longevity and performance in varied environmental conditions. Additionally, the ease of use in extreme conditions—owing to their smooth operation and robust construction—further cements their status as a preferred choice in demanding scenarios.

The growing popularity and demand for camouflage resin zippers can be attributed to their versatility and reliability. Emerging markets and innovative product designs continue to explore new applications for these zippers, expanding their reach and influence across different sectors. As industries strive for products that offer both utility and aesthetic appeal, camouflage resin zippers are poised to remain a vital component in a multitude of applications.

Product Details:

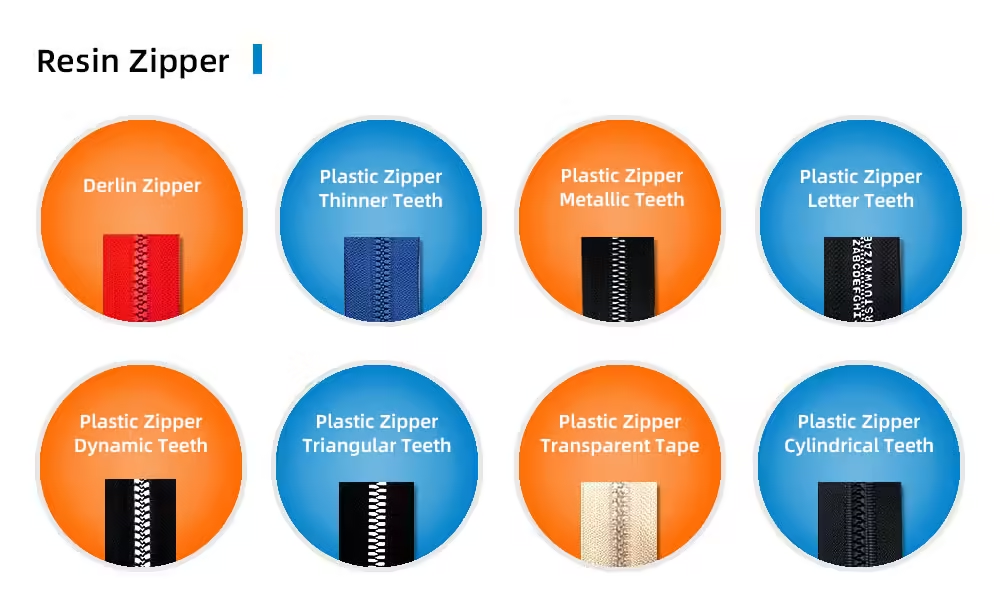

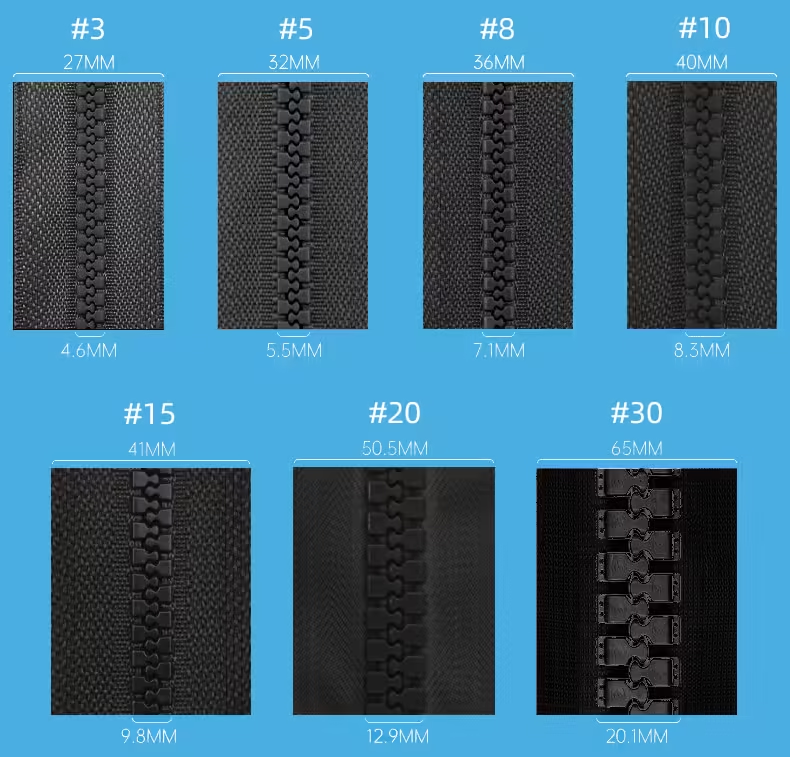

Plastic Zipper Size

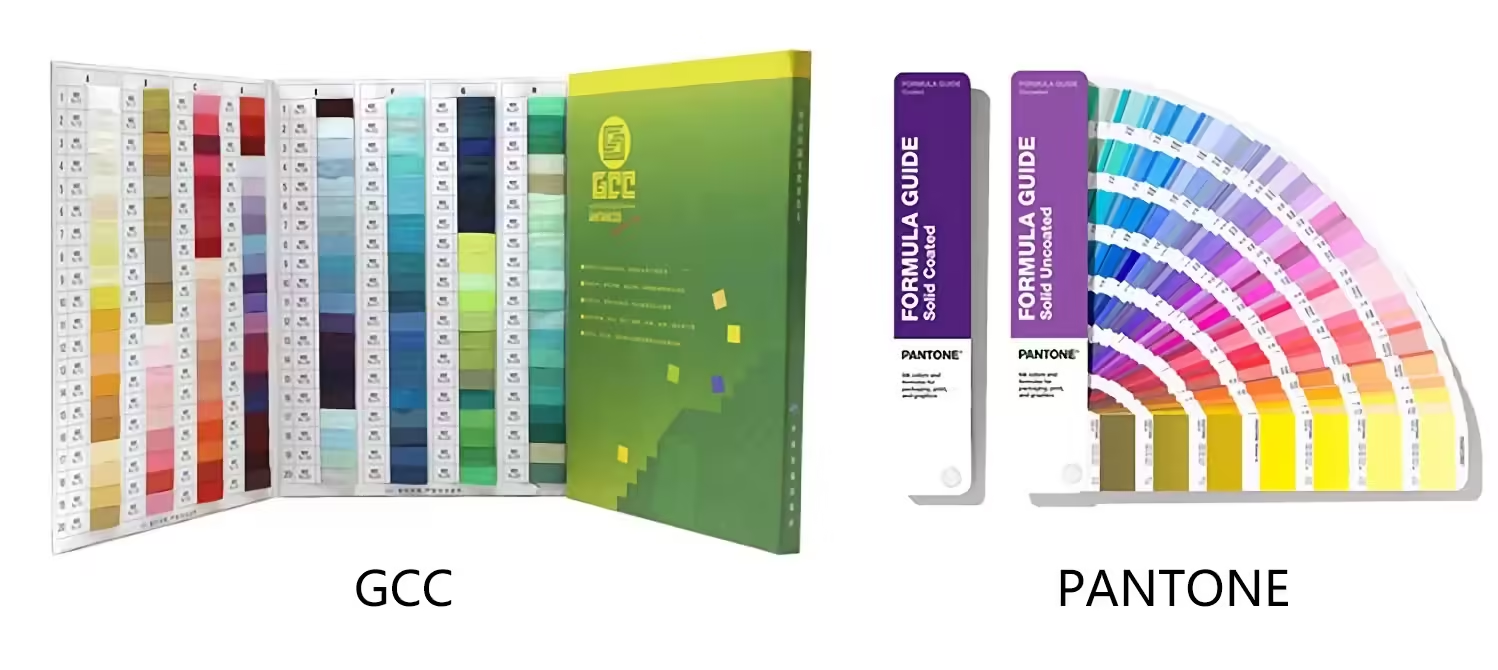

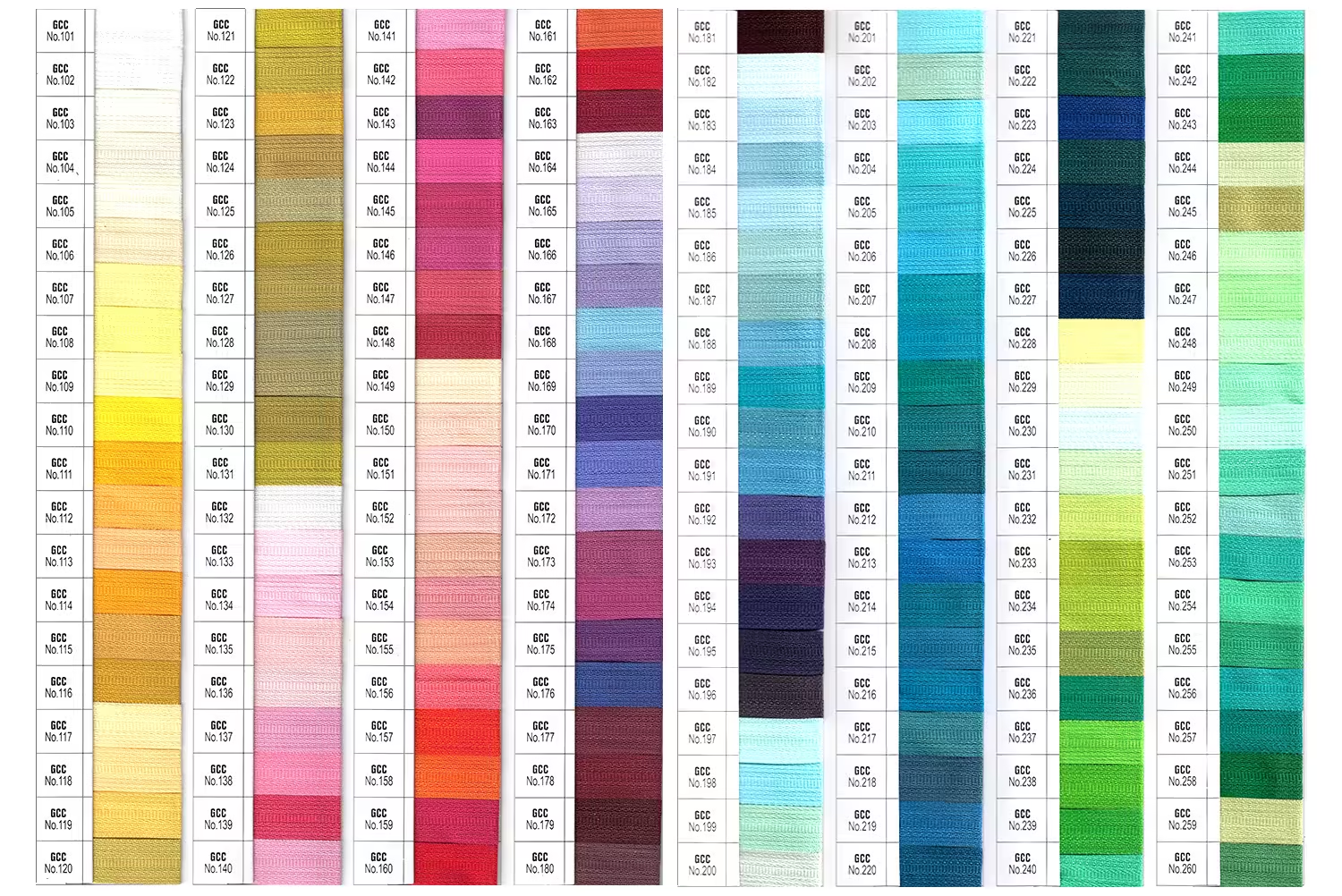

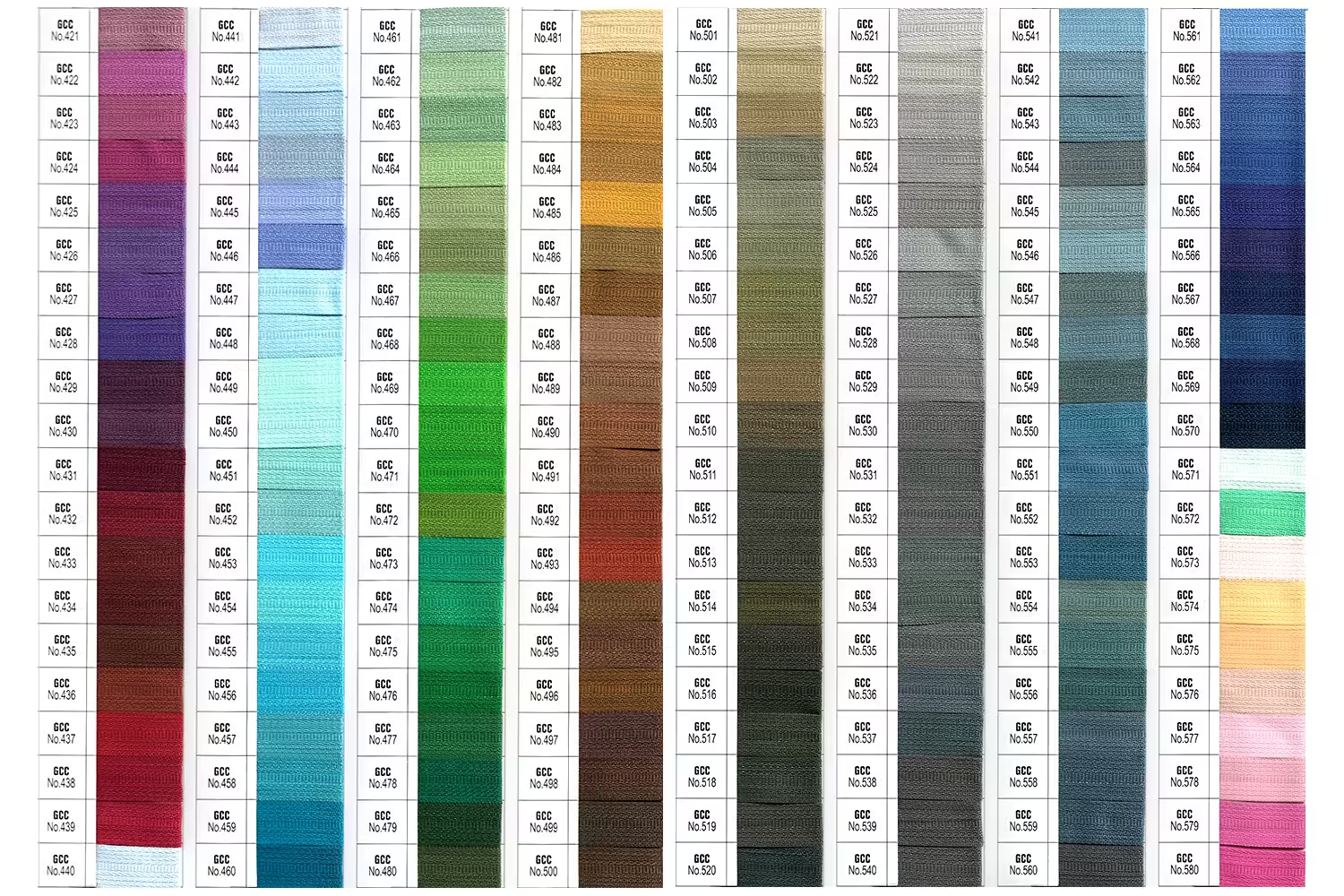

Custom Color

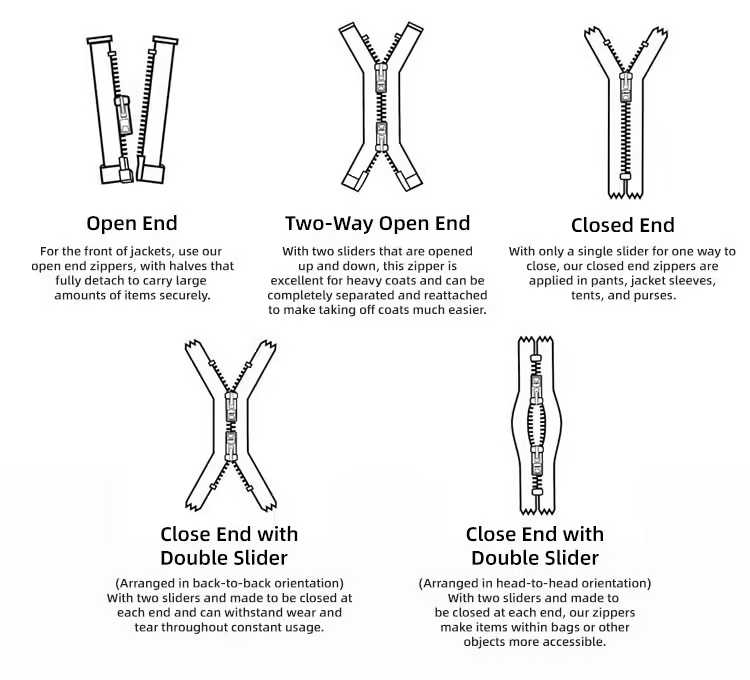

Custom Type

Standard Open-End Zipper

Use for the front of jackets, coats, and skirts.

Two-Way Open-End Zipper

Two-Way Open-End zipper can open and down, this zipper is excellent for long coats and can take off coats much easier.

Standard Closed-End Zipper

One-way closed-end zippers are applied in pants, pouch sleeves, pillows, and purses.

X Shape Close-End Zipper

(back-to-back orientation)Mainly used in tents, and mosquito nets.

O Shape Close-End Zipper

(head-to-head orientation) O Shape Close-End Zippers make items within bags or mattresses.

HAVE QUESTIONS? WE ARE READY TO ANSWER!

You can send inquiries to get free quotes, plans, and exclusive services.

We will reply to you with all your questions within 24 hours.