No.8 Plastic zipper

No.8 Plastic zipper

Wholesale 5# size zipper for garment manufacturing bags custom zipper plastic zipper

Additional information

| product | plastic zipper |

|---|---|

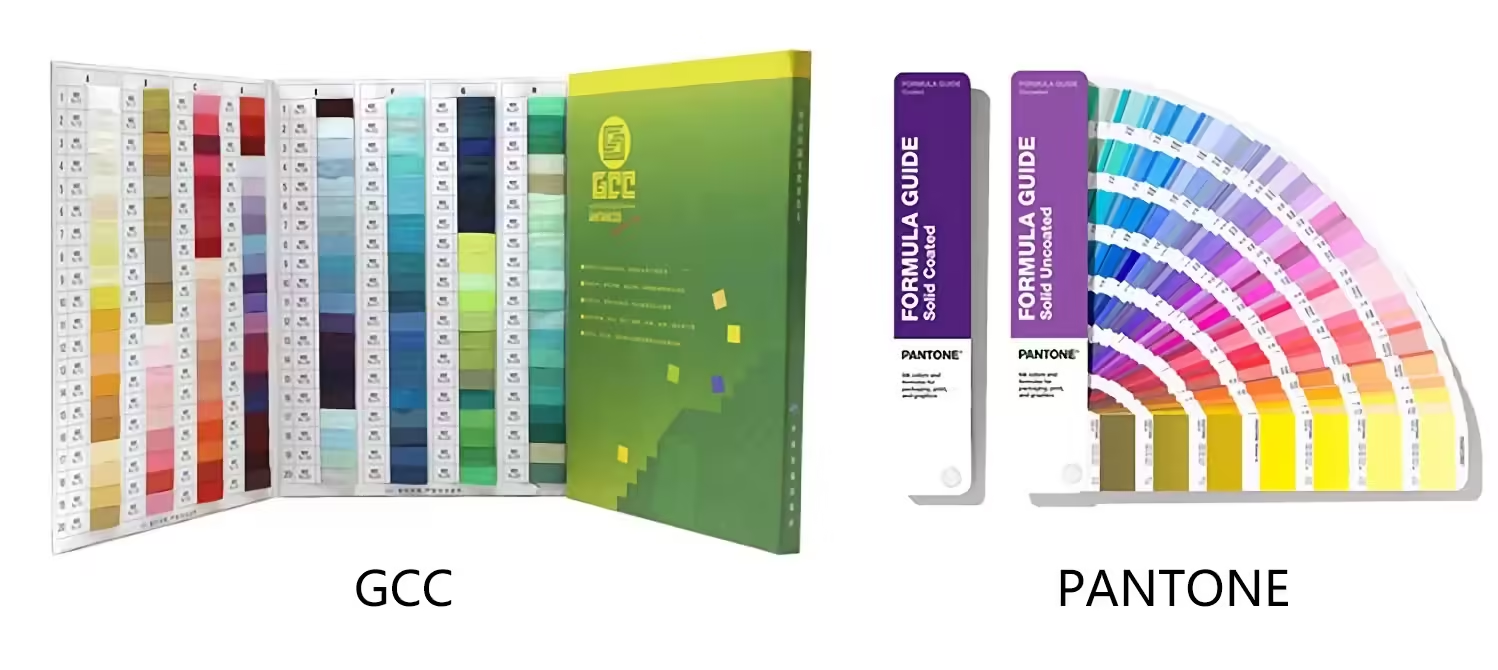

| color | Customized |

| size | 8# |

| Length | Customized |

| application | clothing,bag |

This product personalised to individual customer designs, so no fixed pricing.Pricing will depend on material, size, colours and quantity. Read more on the FAQ.

Introduction to No. 8 Plastic Zippers

No. 8 plastic zippers are a specific type of zipper characterized primarily by the width of their teeth when closed, which measures approximately 8 millimeters. These zippers are widely used in various applications due to their unique blend of durability, flexibility, and resistance to environmental factors. The materials typically used in No. 8 plastic zippers include high-grade polymers that offer excellent resistance to moisture and UV rays, making them suitable for both indoor and outdoor use. This section will provide an overview of what No. 8 plastic zippers are, including their specific characteristics and common uses.

The construction of No. 8 plastic zippers involves molded plastic teeth, which are robust enough to withstand significant wear and tear. Unlike metal zippers, which can corrode over time, plastic zippers maintain their integrity even in harsh environments. This makes them ideal for outdoor gear, marine applications, and garments that frequently come into contact with water. Moreover, the flexibility of plastic zippers ensures smooth operation, reducing the risk of jamming or misalignment.

When comparing No. 8 plastic zippers to other types like metal and coil zippers, several key differences emerge. Metal zippers, while strong, are prone to rust and can be heavier, which may not be suitable for lightweight materials. Coil zippers, on the other hand, are made from coiled nylon or polyester and offer greater flexibility than metal but may not provide the same level of durability as plastic zippers. No. 8 plastic zippers strike a balance between these two, offering a reliable fastening solution that is both lightweight and robust.

Common uses for No. 8 plastic zippers include outdoor jackets, backpacks, tents, and various types of luggage. Their ability to resist moisture and UV exposure makes them particularly well-suited for items that will be used in challenging environments. Additionally, the ease of operation and the reduced risk of jamming make them a preferred choice for manufacturers and consumers alike.

Applications and Benefits of No. 8 Plastic Zippers

No. 8 plastic zippers are a versatile component utilized across various industries due to their robust functionality and adaptability. In the fashion industry, these zippers are a preferred choice for jackets and bags, contributing to both aesthetic appeal and practical use. The lightweight nature of No. 8 plastic zippers makes them ideal for clothing, reducing the overall weight without compromising on strength. Fashion designers often favor these zippers for their ease of use and the wide range of colors and finishes available, allowing for creative freedom in garment design.

For outdoor gear, No. 8 plastic zippers are indispensable. They are commonly integrated into tents, sleeping bags, and backpacks. Their resistance to corrosion is particularly advantageous in outdoor settings, where exposure to moisture and varying weather conditions is inevitable. The durability of these zippers ensures that outdoor enthusiasts can rely on their gear during rigorous activities. Moreover, the smooth operation of No. 8 plastic zippers facilitates quick and easy access to gear, which is crucial in outdoor environments.

In industrial applications, No. 8 plastic zippers are utilized in protective covers and utility bags, where they offer both protection and convenience. Their cost-effectiveness makes them a viable option for large-scale manufacturing, while their robust design ensures longevity and reliability. Testimonials from manufacturers highlight the zippers’ efficiency in production and their positive reception among consumers for their durability and ease of use.

To ensure the longevity of No. 8 plastic zippers, proper maintenance is essential. Regular cleaning with a mild soap solution can prevent the buildup of dirt and debris, which can impede functionality. Lubricating the zipper with a silicone-based product can also enhance its performance, ensuring smooth operation. By following these maintenance tips, users can extend the lifespan of No. 8 plastic zippers, maintaining their effectiveness and reliability over time.

Product Details:

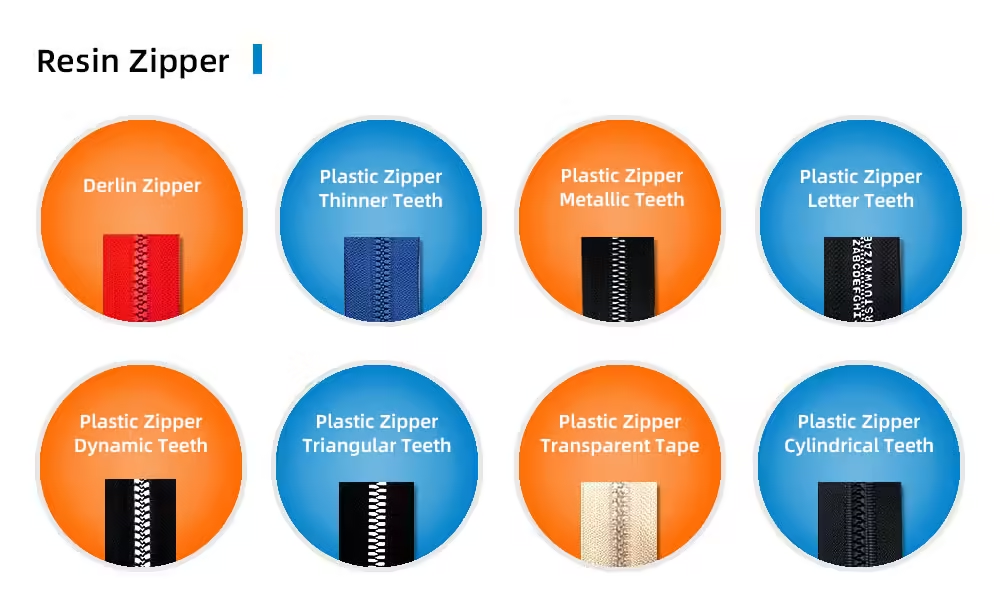

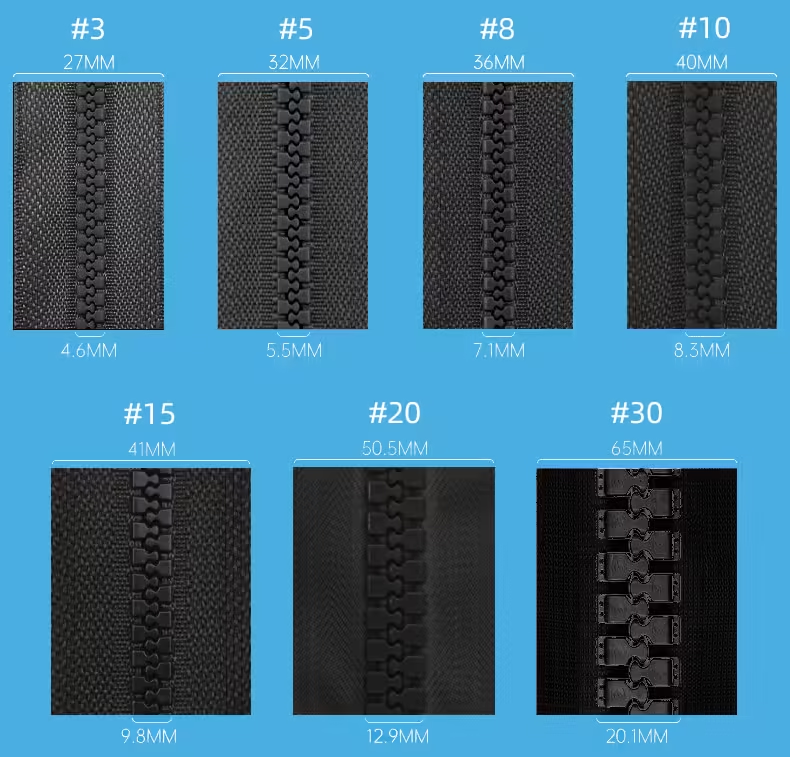

Plastic Zipper Size

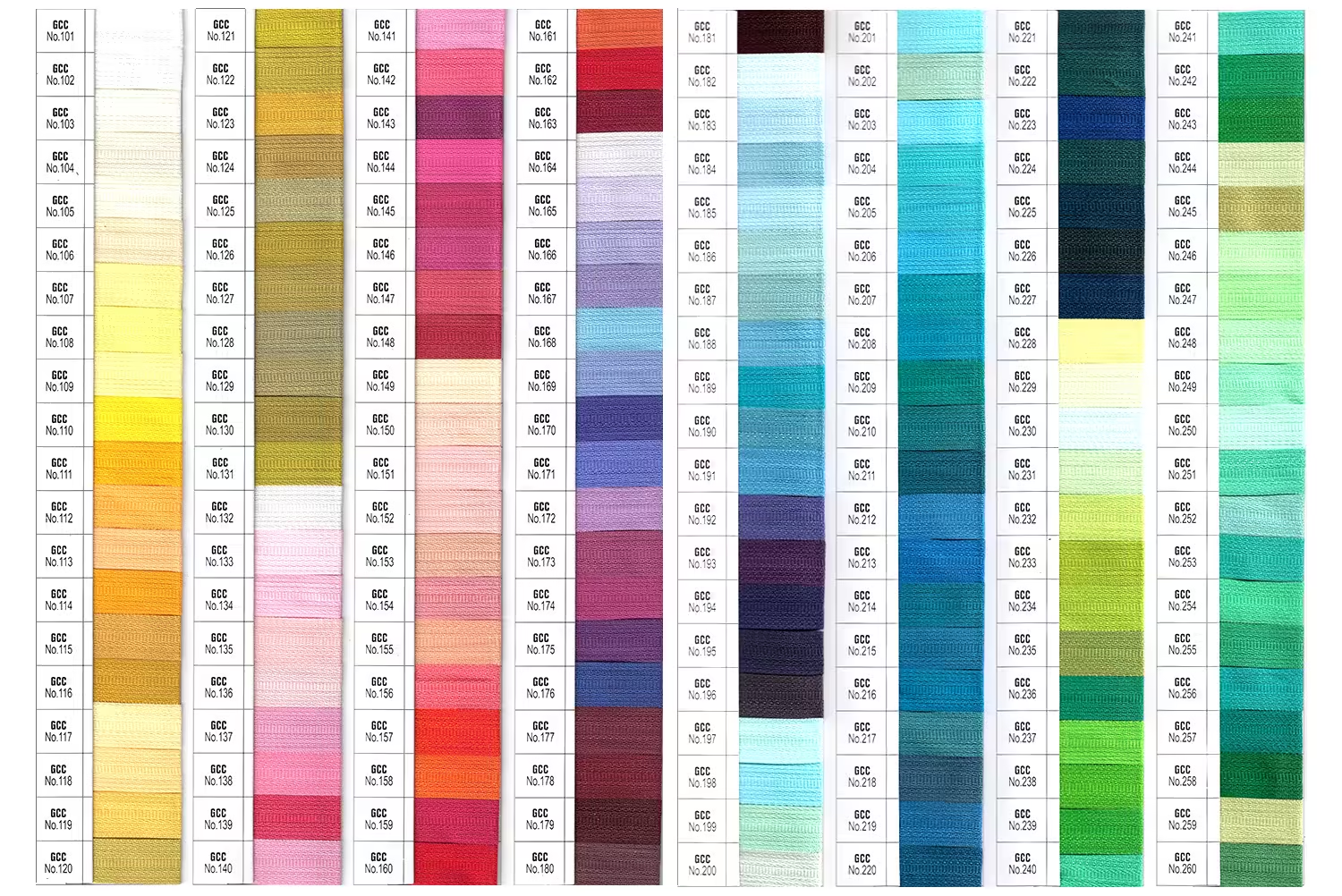

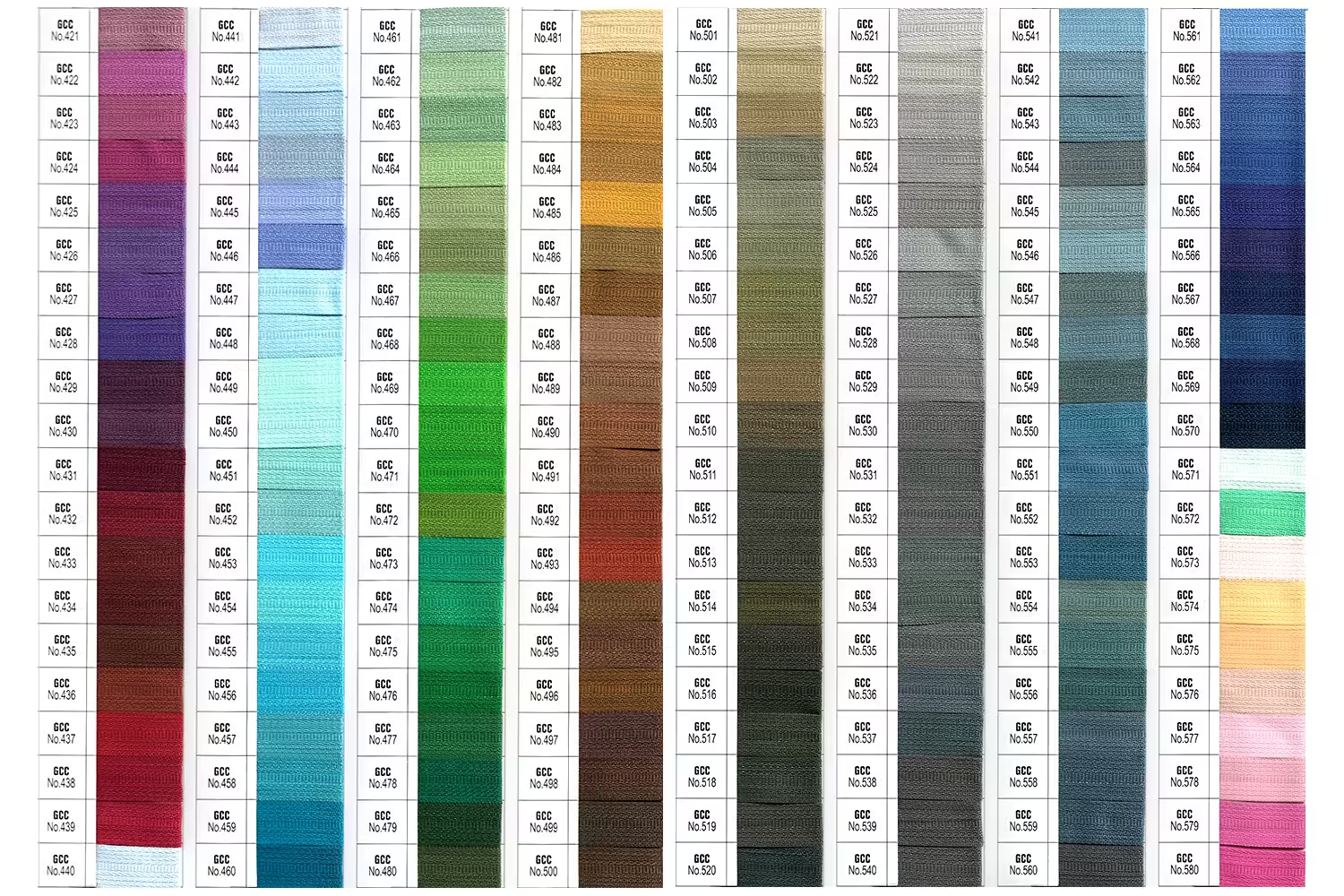

Custom Color

Custom Type

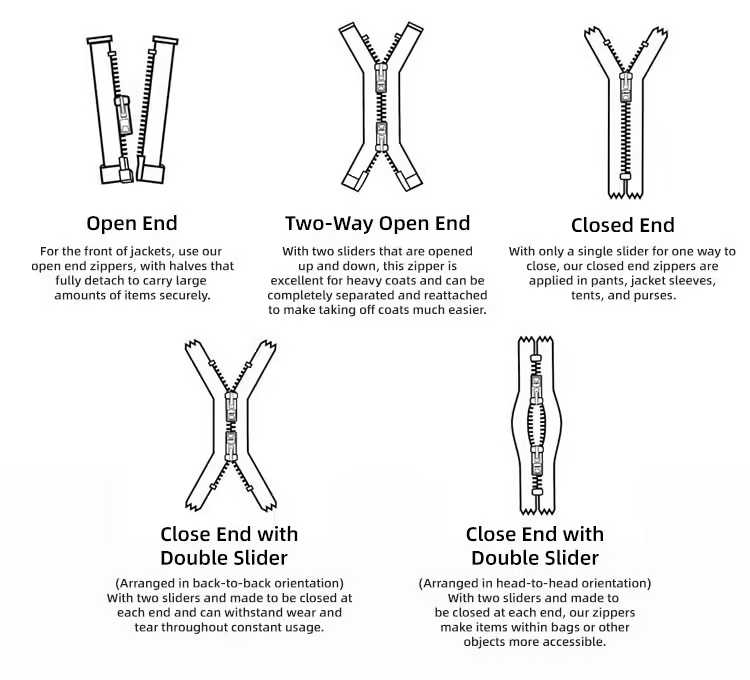

Standard Open-End Zipper

Use for the front of jackets, coats, and skirts.

Two-Way Open-End Zipper

Two-Way Open-End zipper can open and down, this zipper is excellent for long coats and can take off coats much easier.

Standard Closed-End Zipper

One-way closed-end zippers are applied in pants, pouch sleeves, pillows, and purses.

X Shape Close-End Zipper

(back-to-back orientation)Mainly used in tents, and mosquito nets.

O Shape Close-End Zipper

(head-to-head orientation) O Shape Close-End Zippers make items within bags or mattresses.

HAVE QUESTIONS? WE ARE READY TO ANSWER!

You can send inquiries to get free quotes, plans, and exclusive services.

We will reply to you with all your questions within 24 hours.