Rotate Double Sided Plastic Zipper

Rotate Double Sided Plastic Zipper

Rotate Double Sided Plastic Zipper Open End Auto Lock Finish Plastic Cremallera With Double Sided Zipper Slider

Additional information

| product | plastic zipper |

|---|---|

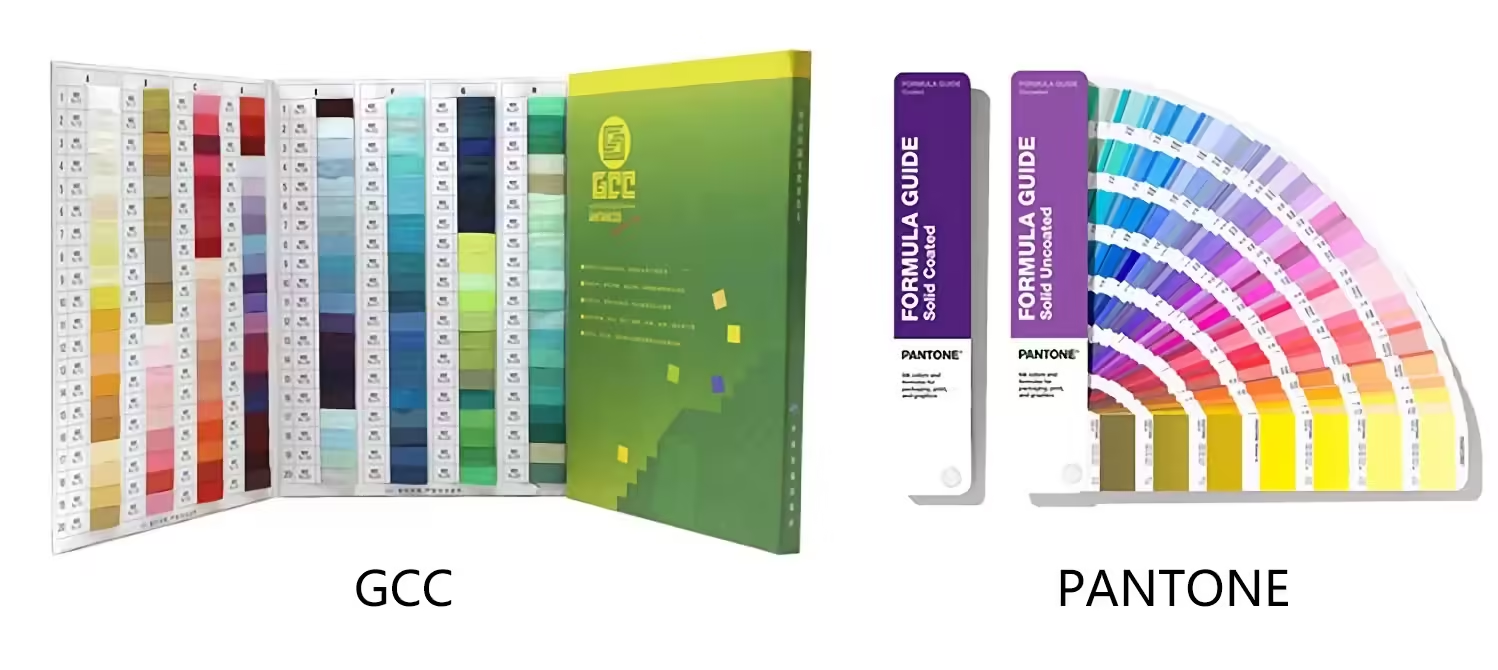

| color | Customized |

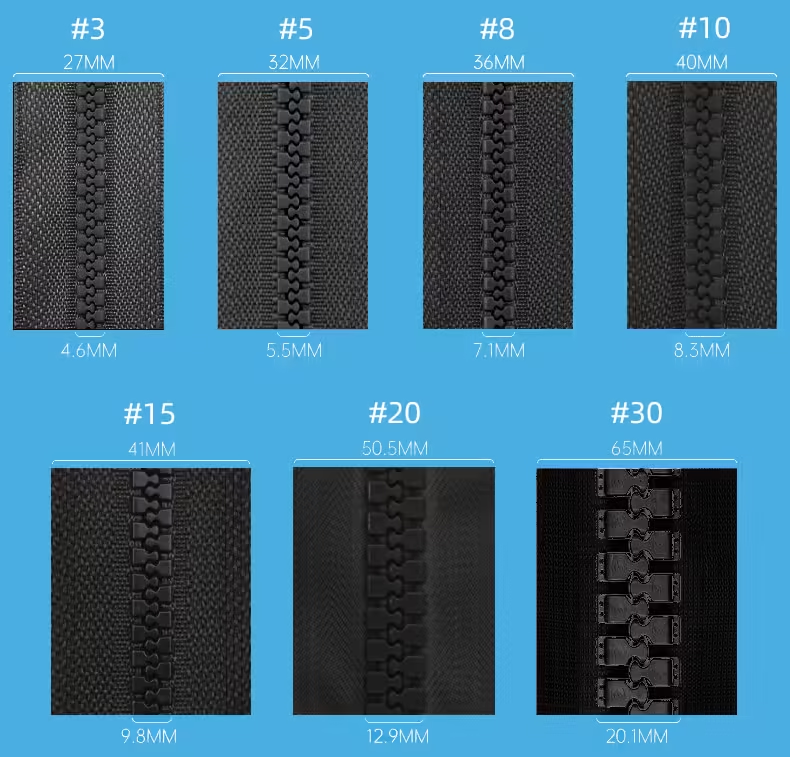

| size | 10#, 20#, 3#, 30#, 5#, 8# |

| Length | Customized |

| application | clothing,textile |

This product personalised to individual customer designs, so no fixed pricing.Pricing will depend on material, size, colours and quantity. Read more on the FAQ.

What are Rotate Double-Sided Plastic Zippers?

Zippers are a fundamental fastening device used in a wide array of products, from clothing to accessories. They consist of two strips of fabric tape, each equipped with interlocking teeth, and a slider that meshes or separates these teeth when moved. Among the various types of zippers available, rotate double-sided plastic zippers stand out due to their unique construction and functionality.

Rotate double-sided plastic zippers are distinguished by their dual-sided design, allowing them to be operated from either side. This feature is facilitated by a rotating mechanism within the slider, enabling it to engage with the zipper teeth from both directions. The materials used in these zippers typically include high-grade plastic, which offers a combination of strength and flexibility. This construction not only enhances durability but also makes the zippers lightweight and resistant to corrosion, making them ideal for a range of applications.

One of the primary advantages of rotate double-sided plastic zippers is their versatility. They are commonly used in items that require access from both sides, such as reversible jackets, bags, and certain types of outdoor gear like tents and sleeping bags. The ability to rotate and operate the zipper from either side adds a layer of convenience for users, making these zippers particularly popular in industries focused on functionality and user experience.

The benefits of using rotate double-sided plastic zippers extend beyond convenience. Their plastic construction ensures they are less prone to rust and wear compared to metal zippers, enhancing their longevity. Additionally, the double-sided feature adds to the overall ease of use, as it allows for more flexible design options and greater accessibility in various applications.

In summary, rotate double-sided plastic zippers offer a unique combination of versatility, durability, and ease of use. Their innovative design and robust construction make them a preferred choice in many practical applications, ensuring both functionality and user satisfaction.

How to Properly Install and Maintain Rotate Double-Sided Plastic Zippers

Installing rotate double-sided plastic zippers requires precision and attention to detail to ensure a secure fit and smooth functionality. Begin by gathering the necessary tools: a measuring tape, scissors, sewing needle, thread, and a zipper foot for your sewing machine. Preparation is key, so start by measuring the length of the zipper against the item you intend to install it on, ensuring an exact fit.

Next, mark the points where the zipper will be attached using tailor’s chalk or a fabric marker. Carefully cut a slit along the marked line, ensuring that the cut is straight and clean. This slit will accommodate the zipper. Align the zipper teeth with the edges of the fabric slit, pinning it in place to prevent shifting during sewing.

Using a sewing machine equipped with a zipper foot, stitch along the edges of the zipper. Begin sewing from the top end, moving slowly to maintain a straight line. If stitching by hand, use a backstitch for added durability. Ensure that the stitches are tight enough to hold the zipper securely but not so tight that they impede its movement. Once sewn, test the zipper to ensure it moves smoothly and adjust if necessary.

Maintaining rotate double-sided plastic zippers is essential for their longevity. Regularly inspect the zipper for dirt and debris, cleaning it with a soft brush or cloth. For optimal performance, lubricate the zipper teeth with a silicone-based lubricant or beeswax, applying it sparingly to avoid buildup. Avoid excessive force when operating the zipper to prevent teeth damage or misalignment. If a zipper gets stuck, gently work it back and forth rather than pulling forcefully.

By following these installation and maintenance steps, you can ensure that your rotate double-sided plastic zippers remain functional and durable, providing reliable performance for various applications.

Product Details:

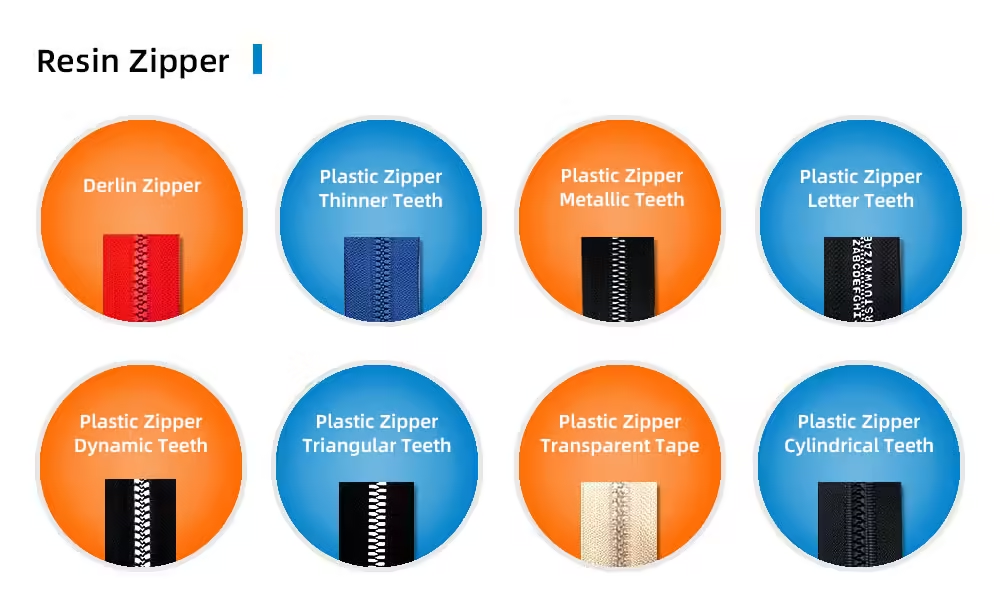

Plastic Zipper Size

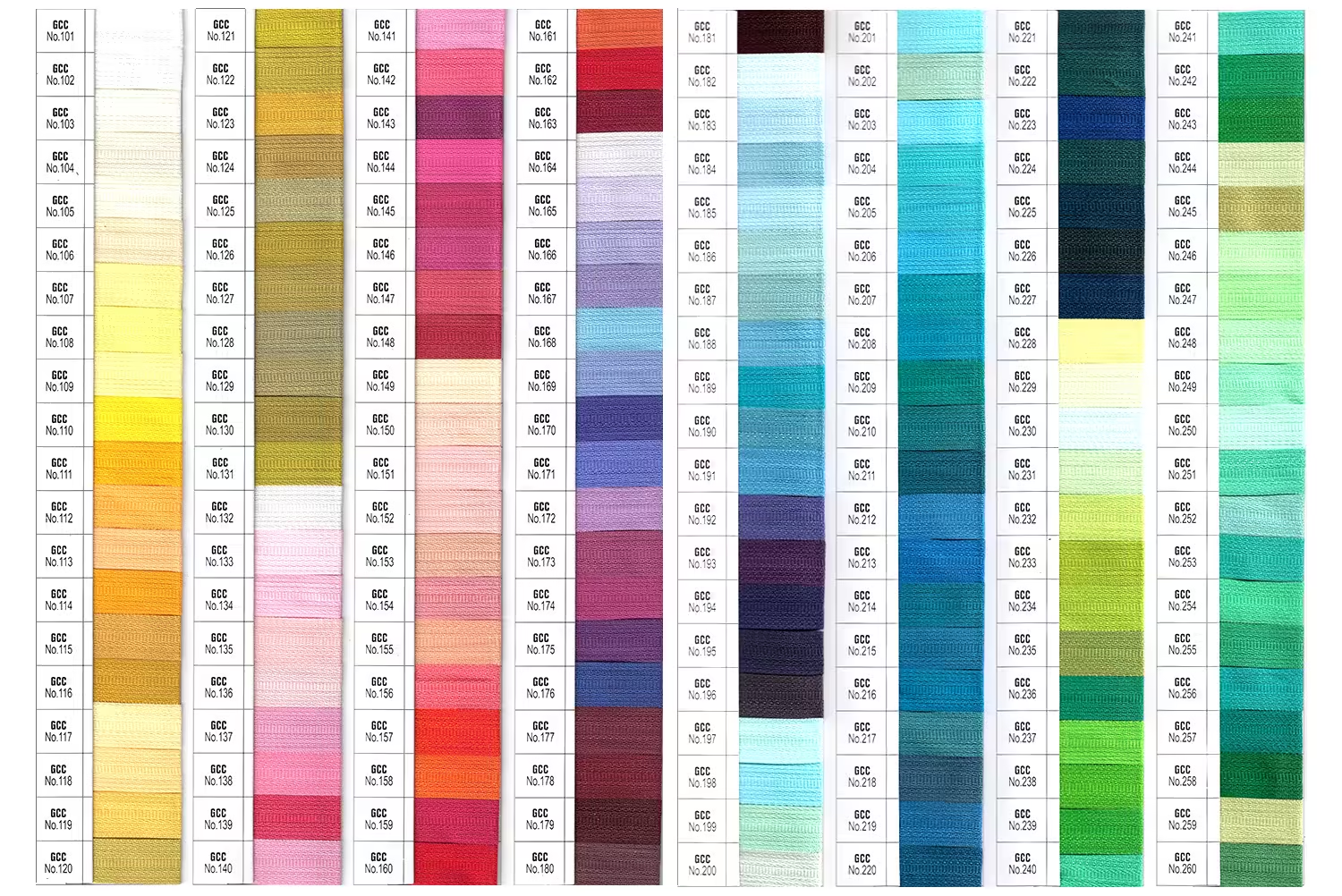

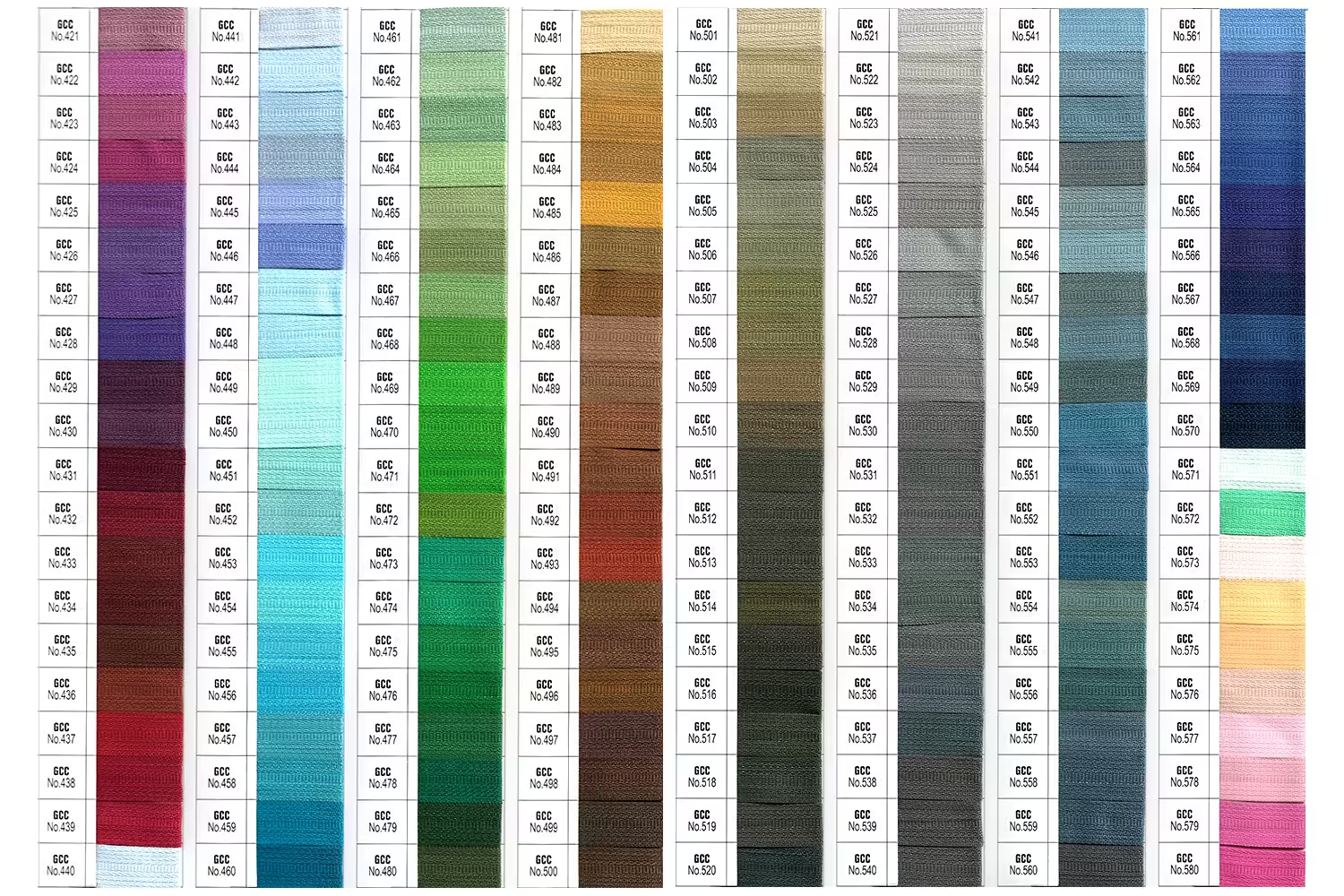

Custom Color

Custom Type

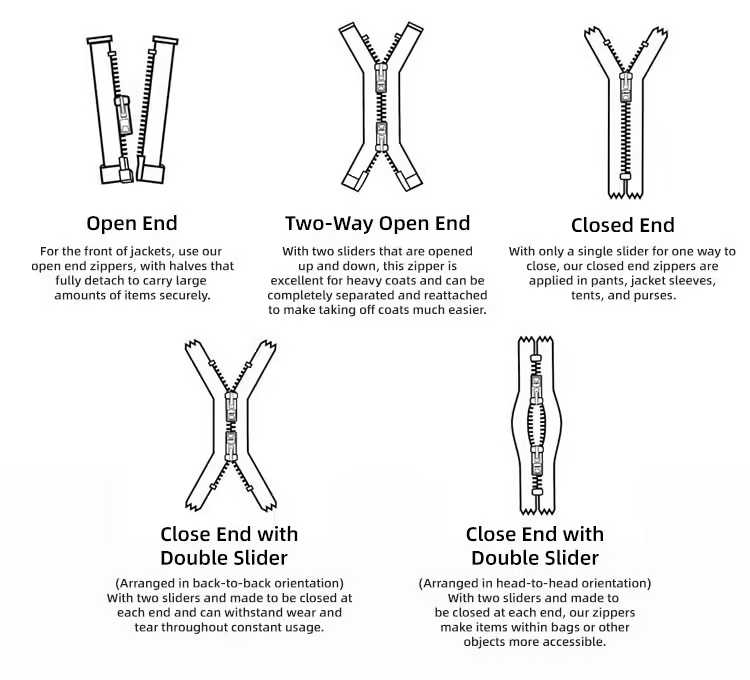

Standard Open-End Zipper

Use for the front of jackets, coats, and skirts.

Two-Way Open-End Zipper

Two-Way Open-End zipper can open and down, this zipper is excellent for long coats and can take off coats much easier.

Standard Closed-End Zipper

One-way closed-end zippers are applied in pants, pouch sleeves, pillows, and purses.

X Shape Close-End Zipper

(back-to-back orientation)Mainly used in tents, and mosquito nets.

O Shape Close-End Zipper

(head-to-head orientation) O Shape Close-End Zippers make items within bags or mattresses.

HAVE QUESTIONS? WE ARE READY TO ANSWER!

You can send inquiries to get free quotes, plans, and exclusive services.

We will reply to you with all your questions within 24 hours.