Track resin Zipper

Track resin Zipper

Intensify Track Plastic Zipper 7# Plastic Zip Reinforced Cremallera Resin Luggage Durable Zipper For Tent

Additional information

| product | plastic zipper |

|---|---|

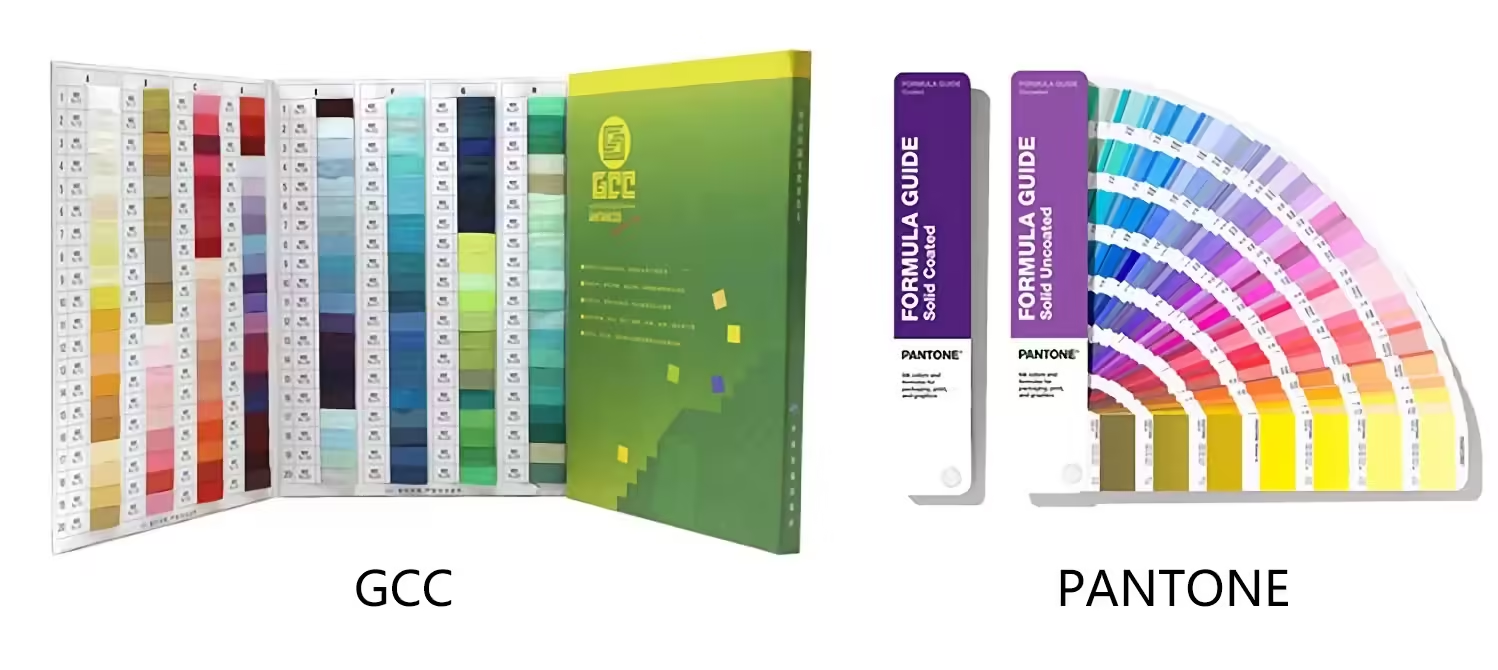

| color | Customized |

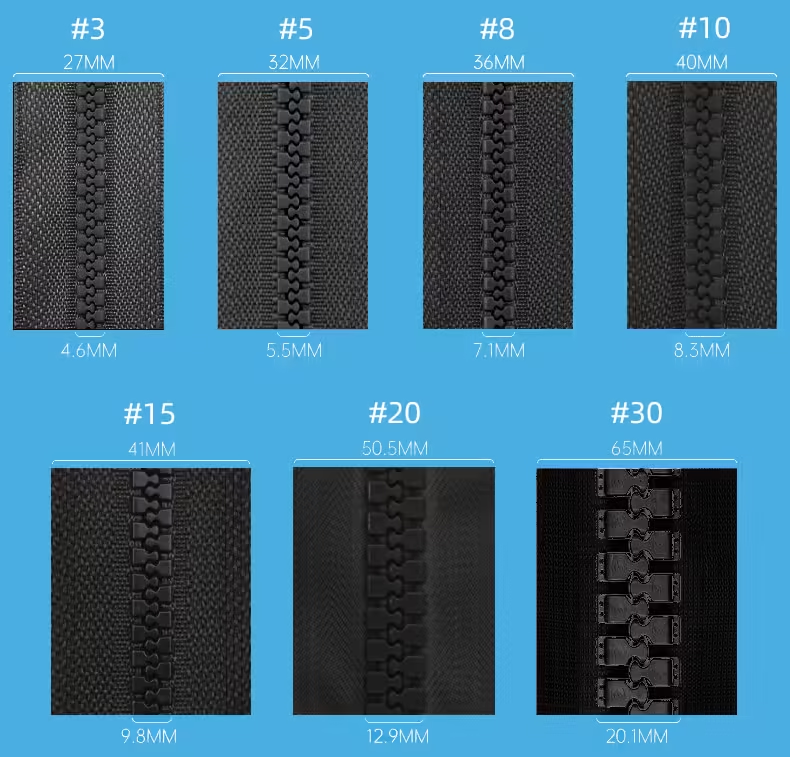

| size | 10#, 20#, 3#, 30#, 5#, 8# |

| Length | Customized |

| application | clothing,textile |

This product personalised to individual customer designs, so no fixed pricing.Pricing will depend on material, size, colours and quantity. Read more on the FAQ.

Introduction to Track Resin Zippers

Track resin zippers are a crucial component in many industries, known for their durability and versatility. These zippers consist of several key parts, each playing a vital role in their overall functionality. The basic anatomy of a track resin zipper includes the slider, teeth, tape, and top and bottom stops. The slider is the mechanism that opens and closes the zipper by moving along the teeth, which interlock to form a secure closure. The tape is the fabric part of the zipper that holds the teeth in place, while the top and bottom stops prevent the slider from coming off the zipper track.

The material properties of the resin used in these zippers are one of the main reasons for their popularity. Resin, a type of synthetic polymer, is chosen over materials like metal or nylon for several reasons. Firstly, resin is lightweight yet strong, providing a balance of durability and ease of use. It also offers excellent resistance to chemicals and environmental factors such as UV radiation and moisture, making it ideal for outdoor applications. Unlike metal, resin does not corrode, and it can be molded into various shapes and sizes, allowing for greater design flexibility.

Track resin zippers find applications in a wide range of industries. In the fashion industry, they are commonly used in garments, bags, and accessories due to their aesthetic appeal and functionality. Outdoor gear, including tents, backpacks, and jackets, often incorporates track resin zippers because of their ability to withstand harsh conditions. In the industrial sector, these zippers are used in products that require durable and reliable closures, such as protective covers and equipment cases.

Understanding the construction and material properties of track resin zippers provides valuable insight into their significance across different contexts. Whether in fashion, outdoor gear, or industrial equipment, these zippers offer a reliable solution for various applications, underscoring their importance in contemporary design and manufacturing.

Enhancing the performance of track resin zippers requires a multifaceted approach that combines routine maintenance with innovative improvements. Proper maintenance is fundamental to ensuring the longevity and smooth operation of these zippers. Regular cleaning with a soft brush or cloth can prevent the accumulation of dirt and debris, which are common causes of jamming. Additionally, lubrication with silicone-based products can significantly reduce friction, ensuring the zipper moves smoothly along its track.

Beyond routine maintenance, advanced techniques can be employed to fortify the durability and functionality of track resin zippers. Reinforced stitching is one such method; by using stronger threads and tighter stitching patterns, the attachment points of the zipper can withstand greater stress, reducing the likelihood of failure. Specialized coatings, such as water-resistant or anti-corrosive layers, can also be applied to the zipper to enhance its resilience against environmental factors.

Moreover, the integration of hybrid materials is gaining traction as an effective way to boost zipper performance. Combining traditional resin with high-strength fabrics or flexible polymers can create a zipper that is both robust and adaptable. This hybrid approach not only improves strength but also enhances the zipper’s ability to maintain its integrity under varying conditions.

Staying abreast of industry trends and technological advancements is crucial for those looking to optimize track resin zippers. Innovations such as self-healing zippers, which can automatically realign and repair minor damages, are revolutionizing the field. Additionally, the use of computer-aided design (CAD) and 3D printing technologies in zipper manufacturing is enabling more precise and custom-tailored solutions, further enhancing performance.

By combining regular maintenance with these advanced techniques and keeping informed about the latest industry developments, users can significantly enhance the performance and longevity of track resin zippers. This comprehensive approach ensures that these essential components continue to function reliably and efficiently in various applications.

Product Details:

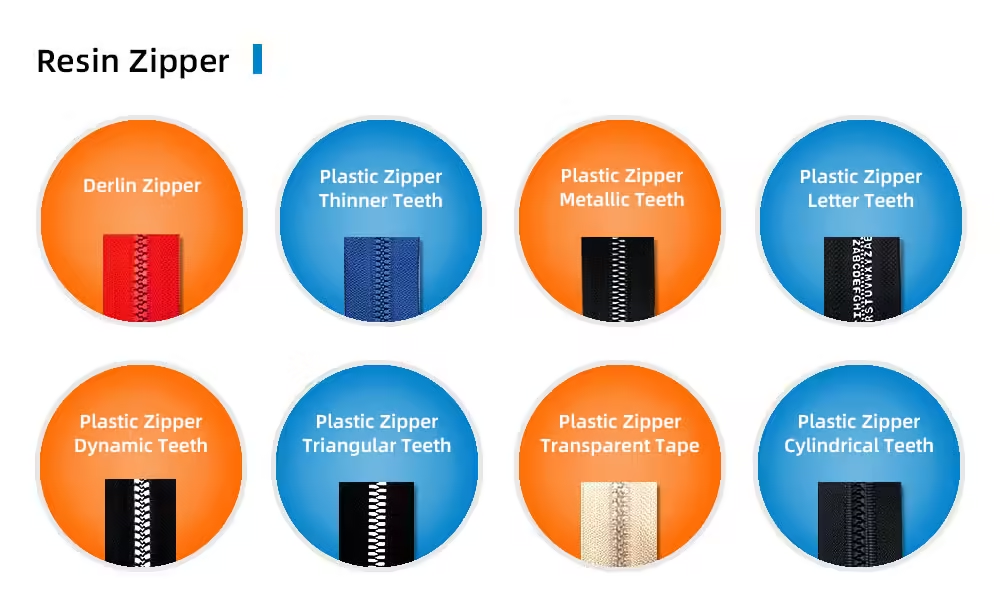

Plastic Zipper Size

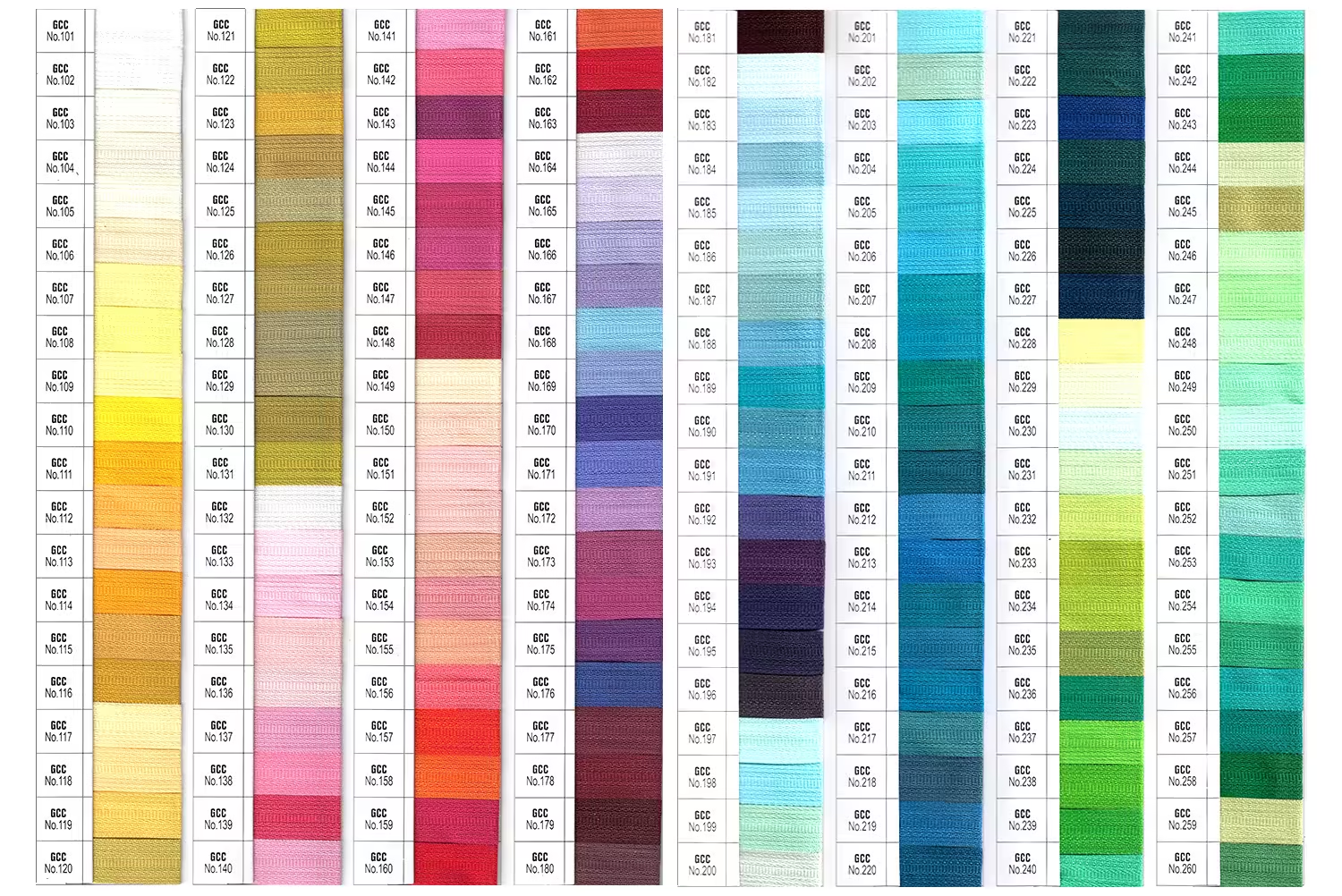

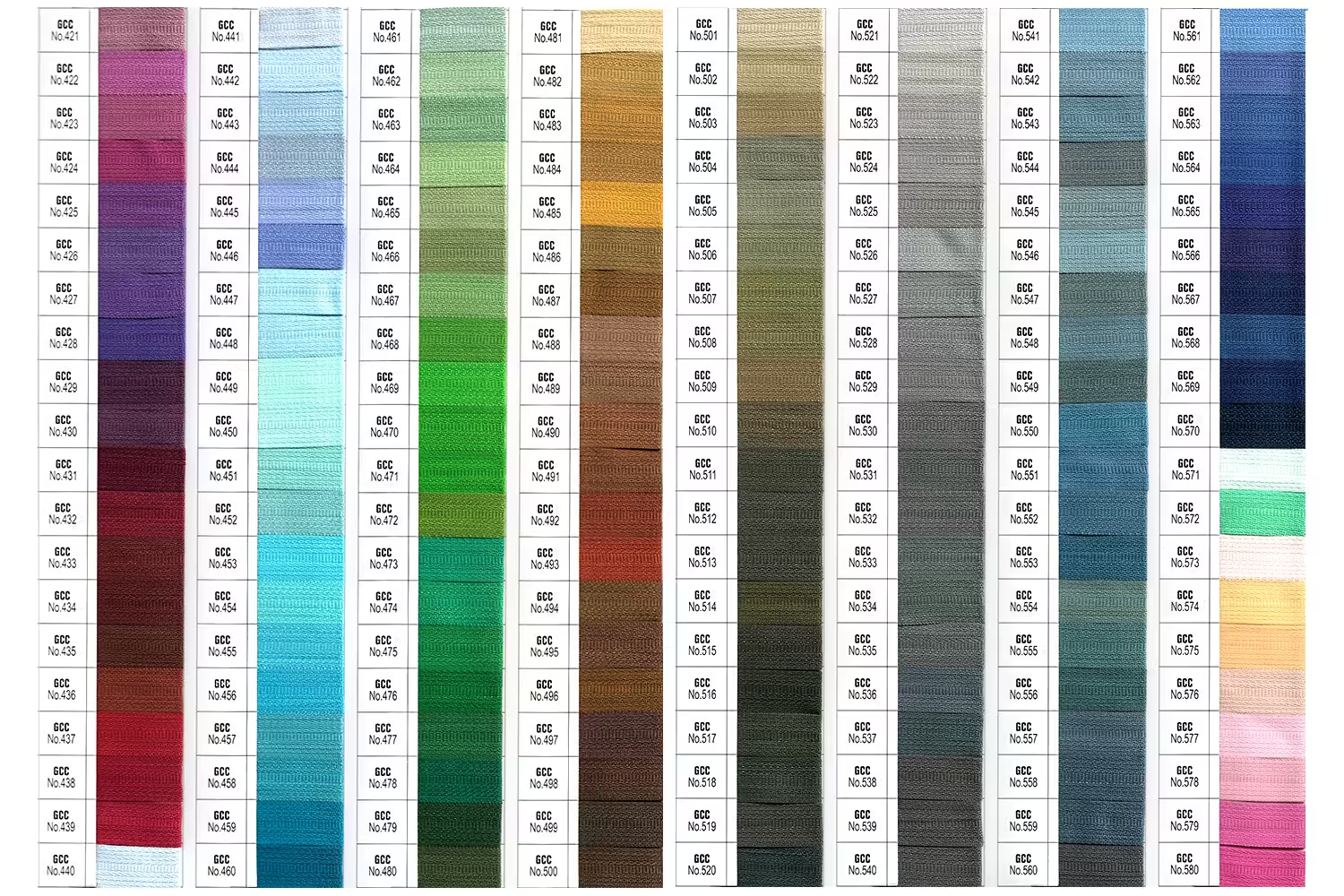

Custom Color

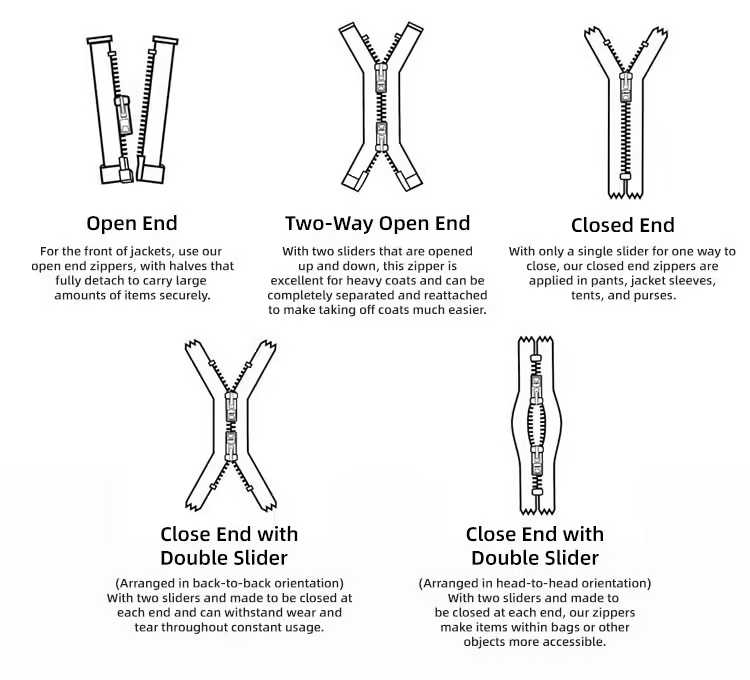

Custom Type

Standard Open-End Zipper

Use for the front of jackets, coats, and skirts.

Two-Way Open-End Zipper

Two-Way Open-End zipper can open and down, this zipper is excellent for long coats and can take off coats much easier.

Standard Closed-End Zipper

One-way closed-end zippers are applied in pants, pouch sleeves, pillows, and purses.

X Shape Close-End Zipper

(back-to-back orientation)Mainly used in tents, and mosquito nets.

O Shape Close-End Zipper

(head-to-head orientation) O Shape Close-End Zippers make items within bags or mattresses.

HAVE QUESTIONS? WE ARE READY TO ANSWER!

You can send inquiries to get free quotes, plans, and exclusive services.

We will reply to you with all your questions within 24 hours.