In the field of functional zippers, waterproof zippers and airtight zippers are two core technologies. Although they seem similar, they have essential differences in performance and application. Waterproof zippers achieve waterproofing through special coatings, while airtight zippers go a step further by completely isolating gases and liquids. This article will delve into the technical principles, classifications, and actual application scenarios of these two types of zippers, revealing their unique values in different fields.

I. Waterproof Zippers and Airtight Zippers: Technical Principles and Core Differences

1. Waterproof Zippers: The First Line of Defense Against Water

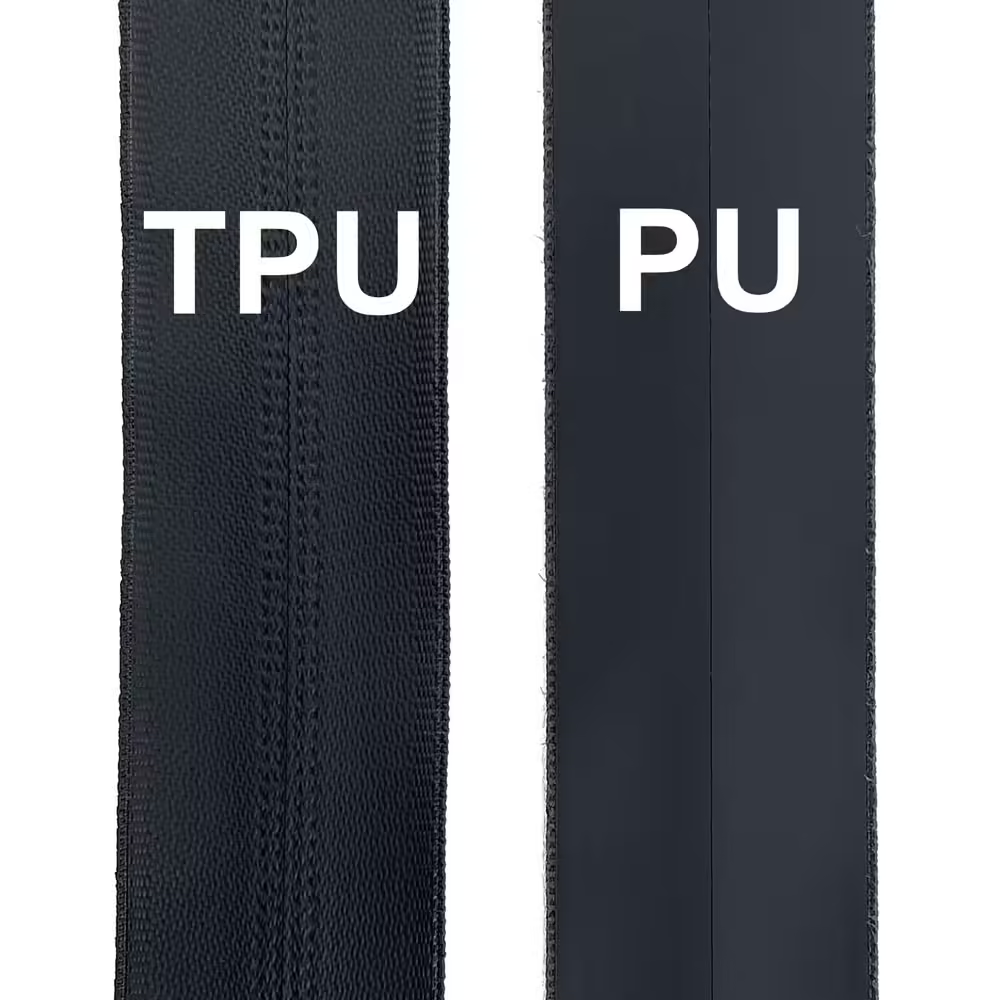

The core of waterproof zippers lies in their surface coating technology. Common coatings include TPU (Thermoplastic Polyurethane) and PU (Polyurethane). These coatings, applied through precision processes to the zipper teeth, form a waterproof barrier that effectively blocks the penetration of liquid water but cannot completely isolate gases.

- TPU Coating: With excellent wear resistance, low-temperature tolerance, and elasticity, it is suitable for outdoor equipment and clothing.

- PU Coating: Thinner and softer, with better breathability, it is commonly used in high-end functional clothing.

2. Airtight Zippers: The Ultimate Solution for Extreme Sealing

Airtight zippers not only provide waterproofing but also completely isolate gases. They employ special designs and materials, such as dual sealing tracks, high-precision tooth structures, and high-performance coatings, ensuring seal integrity in high-pressure or vacuum environments.

- Application Scenarios: Submersible suits, space suits, medical isolation equipment, and other fields with extremely high sealing requirements.

- Performance Indicators: Airtight zippers typically undergo rigorous pressure testing, maintaining seals at depths of 20 meters or under higher pressure.

II. Classification of Waterproof Zippers: Competitive Differences Between Nylon and Resin

1. Waterproof Nylon Zippers: The Perfect Combination of Lightweight and Functionality

Waterproof nylon zippers are known for their lightweight, flexibility, and durability, widely used in outdoor clothing, bags, and tents.

- Features: Lightweight, rich in color, good bending resistance.

- Application Case: A well-known outdoor brand uses waterproof nylon zippers in its raincoats to ensure dryness during heavy rains.

2. Waterproof Resin Zippers: Synonyms for High Strength and Durability

Waterproof resin zippers offer higher strength and wear resistance, suitable for scenarios requiring greater tensile strength and harsher environments.

- Features: Corrosion-resistant, high-temperature resistant, excellent impact resistance.

- Application Case: An international bag brand uses waterproof resin zippers in its heavy-duty travel bags to provide reliable protection during long journeys.

III. Application Scenarios: From Outdoor Adventure to Medical Protection

1. Outdoor Equipment: The Main Battlefield for Waterproof Zippers

- Tents: Waterproof zippers ensure that tents remain dry in heavy rain. For example, a top outdoor brand uses fully waterproof zippers in its four-season tents.

- Backpacks: Waterproof nylon zippers offer a lightweight waterproof solution for climbing bags.

- Clothing: Outerwear like windbreakers and ski suits rely on waterproof zippers to withstand harsh weather.

2. Medical Equipment: The Precise Protection of Airtight Zippers

- Medical Protective Suits: Airtight zippers ensure medical staff remain uncontaminated during surgeries or in isolation environments.

- Medical Isolation Equipment: Used in isolation chambers or negative-pressure wards to prevent the spread of viruses or bacteria.

3. Industrial Protection: Reliable Assurance in Extreme Environments

- Chemical Protective Suits: Waterproof resin zippers resist chemical erosion.

- Fire Suits: Airtight zippers provide safety in high-temperature, high-pressure environments.

IV. Future Trends: Smart Coatings and Multifunctional Integration

1. Smart Coating Technology

Future waterproof zippers might integrate smart coatings, such as:

- Self-Healing Coatings: Automatically repair minor scratches, extending service life.

- Thermosensitive Coatings: Adjust breathability based on environmental temperature, enhancing comfort.

2. Multifunctional Integration

- Antibacterial Function: Incorporate antibacterial components into coatings, suitable for medical and outdoor scenarios.

- Energy Harvesting: Convert zipper motion into electricity using piezoelectric materials to power wearable devices.